Software demand grows for projects

01 September 2016

JIM BARR* highlights the importance of selecting the right software for designing projects that use reinforced concrete technology.

The days of the square box are gone. Replaced by owner demands for more complex structures to be built faster than ever before, the design of today’s reinforced concrete structures are far innovative than they were in the past.

However, one thing has largely remained the same and that is the need for engineers and designers to still produce drawings, and detail and fabricate to get the structure built. In the structural steel world, enhancements made to BIM (building information modelling) software has allowed for nearly seamless design to happen – from concept and analysis to design and detail to fabrication.

The same can be said for software that aids in the design of reinforced concrete projects. However, it has only been in recent years that this technology has been used on a wider scale. And the increased usage has caused software vendors to aggressively compete to capture market share in the reinforced concrete industry.

Before investing in any software technology for concrete reinforcement, however, engineers, designers, detailers and fabricators should have a good understanding of what is available in the market. Some very important points to consider when deciding which concrete software is best for a business include:

• Ease of use: When using any type of software application, user experience is key. That’s no different when it comes to reinforced concrete technology. The ease of drawing creation and sheet layout is vital. The software should perform drawing production in ways that are familiar to users: sections, plans, elevations, and details.

|

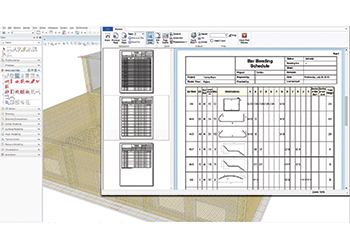

The format of bar bending schedules, for instance, should be customisable. |

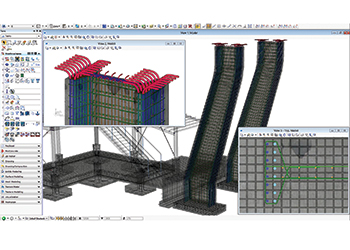

• Reduce risk: When changes are made to the 3D model, a good software application will automatically reflect these changes in the drawings without user intervention. This greatly mitigates risks when the manual updates get removed from the process. Additionally, modern drawing methods should be supported, such as superimposing the 2D sections onto the 3D model. This also reduces risk and lets the user align his 2D with his 3D model.

• Accurate reporting: Reporting should be 100 per cent accurate when it comes to concrete quantities and rebar material lists. Rebar should be given common bar marks using the typical marking schemes chosen by the customer. Also, to minimise fabrication and construction costs, a good software application will allow the user to automatically group to reduce the number of unique bars. Customisation should also be available so that the user can easily customise the format of all bar bending schedules, quantity reports, and material lists.

• Display in 2D and 3D: It is hard to calculate the number of reinforced concrete drawings produced during the past 50 years using simple lines and dots/circles for rebar. A chosen application should support all the typical ways of displaying the rebar in a 2D format, as well as all typical labelling styles. All the data should be derived from the 3D model and consistently maintained and updated so the user is working on the most up-to-date model.

• Exporting and sharing models: The software should be part of the entire project lifecycle. For instance, the software should have an application that allows the user to utilise reinforcing models on mobile devices for construction, to detect clashes between rebar, and allow clients to review models when possible without installing heavy desktop applications. Also, any 3D models created should be usable by downstream solutions for automated bar shearing, automated bar bending, bar tagging, bundling, and shipping.

Adhering to these five tenets when researching software to design the reinforced concrete section of a project will reduce risks and save costs, and contribute to a greater return on investment.

*JIM BARR is director of product management, structural with Bentley Systems, a leading global provider of comprehensive software solutions for advancing infrastructure.