Cutting costs through proper insulation

01 June 2017

MOHAMMED SANAOBAR, regional technical director of Wacker Chemicals Middle East, emphasises that the right kind of thermal insulation can reduce energy costs in buildings by up to 60 per cent.

Buildings around the world consume about 40 per cent of primary energy and generate 30 per cent of carbon emissions. This is especially so in the Middle East, where air-conditioning accounts for the lion’s share of private energy consumption, particularly in summer, when rooms need to be cooled.

However, the better a building is insulated the less energy needed for providing a healthy and comfortable living environment. ETICS (exterior thermal insulation composite systems) also called EIFS (exterior insulation and finishing systems) are the simplest and most reliable method of preventing energy losses. The systems are applied externally and thus prevent the wall material from heating up unnecessarily.

ETICS were developed in Europe in the early 70s and since then have proven itself through numerous studies and field tests. The most popular ETICS are based on expanded polystyrene panels (EPS). But since polystyrene boards don’t form a stable bond with cement, polymer-modified adhesive mortars are needed. Adhesive mortar with just three to four per cent of polymer powders can form a stable and permanent bond with the polystyrene board and ensures that the insulation material adheres well to the facade.

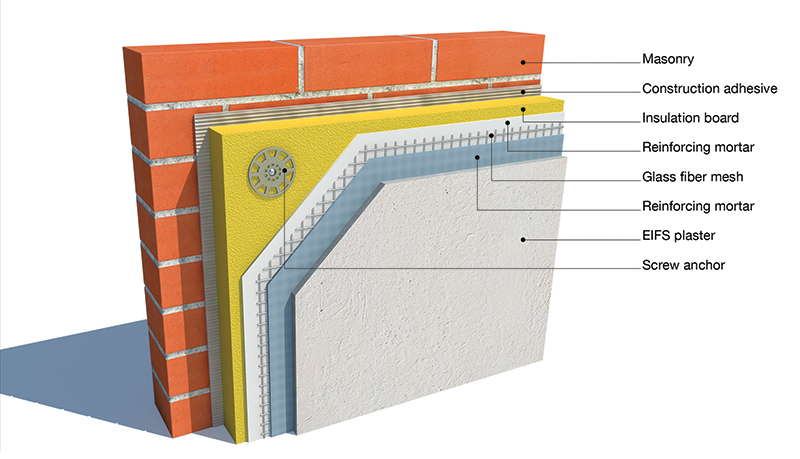

In order to protect the soft EPS from damage, a 3- to 4-mm-thick polymer-modified cement-based mortar – the so-called base coat – is applied on top, embedding a special reinforcing fibre mesh. Finally, a 2- to 3-mm-thick finishing coat is applied to provide a decorative and protective surface (Figure 1).

The outstanding performance and durability of ETICS dry-mix mortars is achieved by combining the mineral binder Portland cement with organic binders in the form of dry synthetic polymers, namely dispersible powders. These binders are produced by a spray-drying process of special waterborne dispersions based on vinyl acetate and ethylene. The polymer powder redisperses during the mixing of the dry-mix mortar with water and forms a durable film during the drying of the mortar. This polymer film acts as an organic binder, glues together the filler particles, reinforces the mortar structure, makes the mortar more flexible and provides an excellent adhesion.

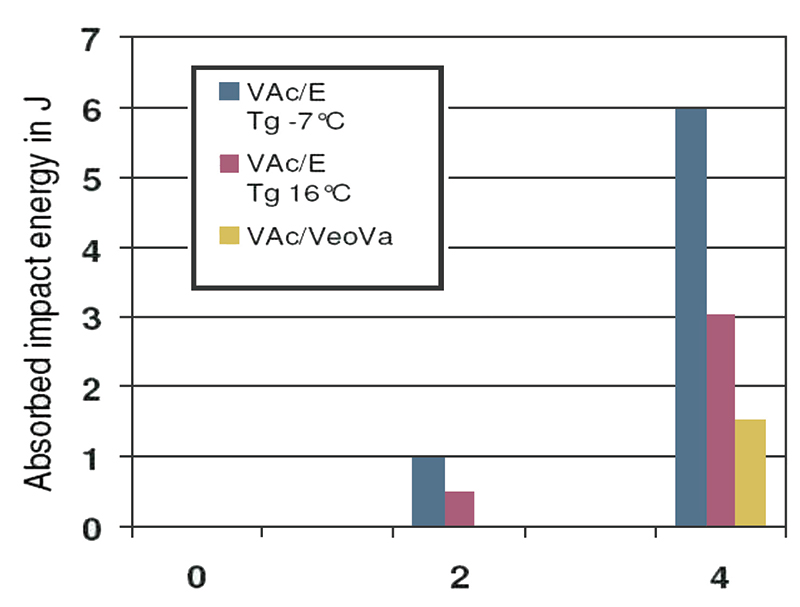

The base coat is predominantly responsible for the mechanical properties and resistance of the ETICS and protects the soft insulation material. Thus, the base coat must have not only have a good adhesion to the EPS but also show high flexibility and impact resistance. The latter can be determined by the so-called hard body impact test: where different steel balls are dropped from different heights, corresponding to a certain impact energy given in Joules (J). Figure 2 shows the impact resistance depending on the amount and type of dispersible powder used. Polymers based on vinyl acetate-ethylene copolymers (VAE) show a better impact resistance compared to vinyl acetate-versatic acid.

ETICS & energy saving

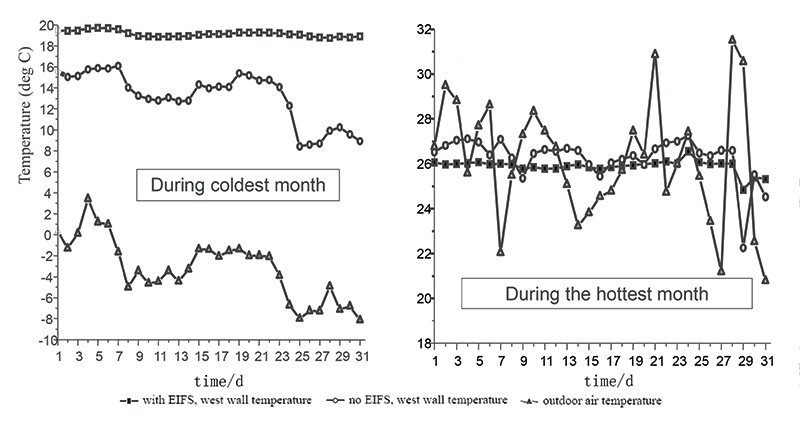

According to a 2003 study conducted by Wacker and China’s Ministry of Housing, Urban and Rural Development (MOHURD), energy savings of 74 to 77 kWh per sq m are possible with a proper insulation. In the study, identical model houses (12 sq m indoor area, 2.8 m net height, no window, one insulated door) equipped with and without ETICS were installed in different climate zones (Beijing, Shanghai and Guangzhou). Roofs and floors of the houses had the same structure and were isolated by 5 cm extruded polystyrene boards.

In the more tropical region (Guangzhou), energy saving was 30 to 45 per cent during the winter and 30 to 60 per cent during summer. In a moderately cold region (Beijing), the energy saving was 30 to 50 per cent during the cold season and 14 to 19 per cent during summer (Figure 3). The tests further illustrated that not only the living comfort is increased in the ETICS houses, but also the durability of the building structure is significantly improved.

Conclusion

Let us bear in mind that cooling is not only expensive but also pollutes the environment and ETICS are one of the simplest and most reliable ways of insulating a building. Apart from reducing energy costs, they also create a healthy indoor ambience and actively protect the masonry, thus adding considerable value to an object. While ETICS can be installed in new buildings, they can also be applied to old buildings under renovation. Further, the systems have been regulated and incorporated into national building regulations as a unique thermal cladding system. As insulation thicknesses have increased, the ETICS industry and national governments such as those from the EU have developed specific fire safety regulations for certified ETICS systems. These safety measures incorporate mineral wool-based fire-breaks as a method of greatly reducing the risk of external façade fire spread in the event of fire.

With the Vinnapas grades of high-quality dispersible polymer powders, Wacker Group of Germany has played an important role in the development of these systems since their introduction to the market.

|

|

FIGURE 2: Hard body impact test: Dropping the 1 kg steel ball from 1.02 m height corresponds to a 10 J impact, whereas the 0.5 kg ball dropped from 0.61 m height corresponds to an impact energy of 3 J. VAE-based binders show best results. |

|

FIGURE 3: Model house comparison: Tests showed that insulated walls keep the room temperature steady during the hot and cold seasons, resulting in huge energy savings. |

- Breaking new ground

- Zurn solutions are down to earth

- The ‘Ideal’ flush technology

- Cutting costs through proper insulation

- Technal thrives on sustainability

- Green community takes shape