UniGrip can take on the load

Gripple has innovatively combined two of its products to offer a suspension solution that boasts a higher load performance rating and greater safety.

01 February 2018

Gripple of the UK has successfully combined the functionality and best features of two of its products to offer a single suspension solution that delivers increased speed, higher load performance and easier adjustment.

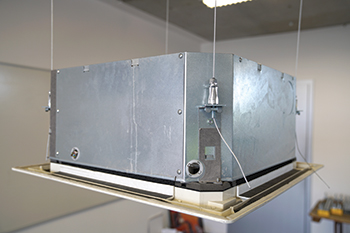

Replacing the Gripple Trapeze and Trapeze Plus, the UniGrip is the next generation of wire rope suspension solution that can be applied to installations in HVAC (heating, ventilation and air-conditioning), and mechanical and plumbing services. With three models, UniGrip boasts an increased load rating performance of up to 33 per cent, each with a greater safe working load (SWL) of 5:1.

“By taking two extremely successful product ranges and rationalising their key benefits, UniGrip is the most comprehensive, value-added, versatile suspension solution Gripple has offered to date. We are excited because we believe that UniGrip is the best alternative to threaded rod on the market today,” says Glenn Bills, Gripple product manager.

The new and patented UniGrip features an attachment to secure it to a substrate at the top and to the service at the bottom, making installation up to six times faster when compared to traditional methods such as threaded rod and channel. This saves contractors’ time and money on site and reduces time working at height, thereby making it a safe solution for installers.

Versatility is added to the UniGrip with the offer of a range of ‘feet’ options which cater for many building services and installation methods. Also added features on the UniGrip are an ergonomically designed button, for ease release and adjustment during installation and a locking indicator, which ensures security afterwards.

As with all Gripple wire suspension solutions, UniGrip arrives on-site in compact, cardboard boxes, as ready-to-use, pre-engineered kits which include the customer’s choice of ‘foot’, specified length of wire and chosen end fixing. This eliminates cutting and filing rod to size on-site – also an important health and safety issue – and requires fewer vehicle movements, meaning less carbon dioxide consumption.

|

Fast Trak ... designed for projects where ceiling space is at a premium. |

Gripple has also launched a quick-installation trapeze bracket solution offering flexibility and efficient use of space, for the installation of electrical containment, pipework, ductwork and other mechanical services in restricted places.

The new product removes labour-intensive on-site activity associated with traditional suspension systems, delivering significant cost and labour savings and carbon efficiencies while minimising health and safety concerns.

With Fast Trak, Gripple leads the way in pre-fabricated, off-site solutions which simplify the process of installing building services. It is up to six times faster than traditional suspension systems, claims a spokesman for the company.

The system comprises lengths of metal track with accompanying brackets, which are used as trapeze brackets for a range of applications, namely electrical containment and ductwork. The brackets range from 309 to 959 mm, and tracks are available in two sizes, 284 mm and 534 mm.

A key element of the system is its adjustability, according to the spokesman.

“The bracket can be moved up and down the track by pressing the latches at each end, to suit the specified height of the installation and allow for minor adjustments. Once at the required height, the bracket ‘clicks’ into place and is then secured with a safety lock. Once tracks are folded, tabs on the bracket can be pushed to 90 degrees to secure the tracks. Each bracket and track system can suspend a maximum weight of 180 kg with a 3:1 safety factor, ensuring the system delivers all the strength of a traditional rod system, with added flexibility and ease of use,” he says.

He adds Fast Trak has been specifically designed for projects where ceiling space is at a premium. The system can be tiered to allow efficient use of space for additional services, making it an ideal solution for residential developments and buildings requiring optimised use of internal space.

Should contractors and architects wish to utilise Gripple’s installation design service to specify Fast Trak, the kits have the added benefit of being labelled by zone, simplifying the storage of materials still further and vastly improving the ease in which product is designated to the correct part of the install. Additionally, customers will be able to download Fast Trak as a BIM (a building information modelling) object from Gripple’s ‘My Gripple’ online login area, enabling the product’s use during installation design and 3D modelling processes.

“Fast Trak is an innovative development for space-saving support systems but it retains its compatibility with standard fixing solutions to ensure a simple, familiar installation process at every stage. Securing the tracks to the ceiling is a quick, two-point fix, using shot fire solutions, drop in anchors or wedges,” the spokesman concludes.

- UD Trucks registers robust sales

- Mabani Steel seals Jeddah mall deal

- Innovation drive at USG Boral

- Knauf AMF offers a ‘quiet beauty’

- UniGrip can take on the load

- The geosynthetics route to durability

- Volvo unveils rigid haulers