BIM brings more planning efficiency

Model-based formwork planning using 3D building information modelling offers transparency in the formwork process, increasing efficiency of the planning process, and planning security, says TOBIAS WALLNER, head of IT Engineering Services at Meva.

01 September 2018

While digitalisation shapes innovation in the construction industry and motivates an entire generation to think in a new way, building information modelling (BIM) in particular unites a wide range of different facets in the sector.

The most striking and innovative aspect about BIM is its holistic approach, which allows all the information about a construction project – from the planning, to the production and manufacturing, and to the time the building is put to use – to be coordinated and managed.

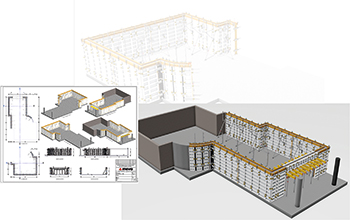

Formwork specialist Meva’s focus is on the shell construction process. However, in BIM, the three-dimensional building model takes centre stage, making it possible not only to define the geometry of the parts depicted but also to assign descriptive characteristics.

Every 3D model accesses a central database and depicts floor layouts and views graphically – from the large complete overview down to the smallest detail such as the bills of material in text-based views.

For example, all formwork components that are to be used are shown. If something is modified in one of these views, this affects the underlying database and thus all other views and lists. Plans are always up-to-date due to the bidirectional associativity (linking). The result speaks for itself: consistent data in plans, views and bills of material.

Communication and transparency are perhaps the most important aspects of BIM. Due to the fact that every participant can access the latest data at any time, information losses can be reduced, and everyone can be sure that the planning status is visible for all other persons involved. But how can a formwork manufacturer position itself to adapt to this innovation?

When talking about formwork, we differentiate between temporary and built-in parts. As the temporary components are only required for the production process of a building, these do not have to be archived in BIM in the long term.

The situation is different, however, for built-in parts such as anchor plates for climbing formwork systems, which constitute an integral part of the building model. In practice, it has proved advantageous to think in terms of discipline-specific models – especially when planning formwork. The formwork model consists solely of formwork objects with formwork and manufacturer-specific information.

To ensure that model-based formwork planning works sensibly, the information in the building model must be complete – and it must be specified. That means that all in-situ concrete and steel-reinforced concrete parts as well as installation surfaces and built-in parts must be specified and classified in terms of building stages, storeys and building cycles.

Time is another factor that should not be forgotten. It is taken into account indirectly in the cycle definition and the manufacturing sequence in the shell construction model. The advantage is that the planning processes become significantly more efficient due to the fact that the formwork supplier no longer needs to gather information and it is no longer necessary to create a new model. The shell-construction and formwork models are combined in a single coordinated model, which enables all participants to communicate with each other. The advantages thus lie in the closed workflow and uniform database.

In order to be able to plan the utilisation of formwork, the model must include all information about the object. At this point, important strategies are defined for the production and handling of the formwork components. For example, if formwork engineers require additional characteristics for in-situ concrete parts, they can find them at any time in the shell construction model.

To unequivocally allocate the formwork objects to the part and individual cycles, they must be depicted and described in the model – and not just alphanumerically. Depending on what the next process is, formwork characteristics can be called up. This information can be classified in formwork, part and process characteristics. This creates transparency in the formwork process, increases efficiency through an object-oriented working method and ensures planning security through an up-to-date planning status and an unequivocal description.

Training

Meva is training key users in many different regions around the world on how insights gained from BIM can be developed. Its engineering department focuses on both the derivation of conventional plan presentations as well as bills of material and also on the generation of the visualisation of model-based formwork planning using corresponding media.

Another area focused on during these pilot projects is the geometrical collision check. The formwork objects are built up intelligently to allow 2D plans to be created and the floor plan and the sections only display the information required for this. Designations can be created and derived automatically and bills of material reflect the current planning status.

The bills of material convince due to flexible filter functions. They thus allow a cycle-specific and/or system-specific evaluation of the modelled formwork components, as all characteristics belonging to the formwork objects are available here. Another advantage of a BIM-capable CAD application is that it provides leeway to create variants. Special solutions can be integrated smoothly into the formwork model, and costs and benefits in the construction process can be analysed quickly and simply.

Meva is pursuing the goal of redefining its place in the Digital Formwork Environment. In doing so, it not only wants to optimise the internal workflow but also wants to support customers throughout the world in the long term. During model-based formwork planning, Meva not only focuses on the planning process but on the production process. The formwork is the determining factor for the shell construction.

The formwork logistics on the construction site can be depicted in an easily comprehensible fashion, and controlled and monitored by means of detailed planning. As the subsequent work steps can be taken into consideration, it is possible to avoid wasting staff time and unnecessary transport for formwork and accessories – both of which are time-consuming and costly. Variant analyses support the optimisation of process sequencing and onsite material requirements.

BIM is part of a change process and requires a new way of thinking. Due to the constant changes and the newly gained insights, the digitalisation strategy and the Meva content (Meva formwork object library) need to be continually adapted as the basis of the formwork model.

That’s why Meva works with cloud-based solutions so it can react quickly, flexibly and comprehensively to changes in the continually evolving world of BIM. This ensures that all persons involved in the planning process can not only access the latest data on the spot but also from anywhere in the world.

BIM can only be used successfully if the processes are adapted to meet the BIM requirements. All persons involved must have the optimised construction process in their sights during every single project in order to exploit the full potential and thus provide the desired value-added for all participants.

Hence, one must build digitally first and then in the real world.

In our opinion, a common approach takes priority during digitalisation of the construction industry. In view of the insights gained, Meva is looking into shaping the future of building construction together with its customers as common goals can only be achieved in a cooperative relationship based on partnership.