Faro enhances QC with new tank analysis tools

01 April 2019

To keep pace with the rapid developments in the architecture, engineering and construction (AEC) industry, 3D measurement, imaging and realisation technology specialist Faro continues to develop its visionary Traceable Construction concept.

The Traceable Construction ecosystem, which includes both products and solutions, outlines the entire portfolio of innovative laser scanning technology and intelligent software tools that Faro offers to leverage the benefits of measured data throughout the various project stages of an object’s BIM (building information modelling) lifecycle.

In February, Faro released a new version of its BuildIT Construction software. Forming an integral part of the ecosystem, the program covers the quality control (QC) workflows in the construction, maintenance and rebuild phases of the BIM lifecycle.

According to a spokesman for Faro, the previous generation version of BuildIT Construction was the first consolidated software and hardware solution designed from the ground up as an end-to-end, fully-integrated building lifecycle QC solution.

“BuildIT Construction compares 3D scan data of as-builts to CAD and BIM models and analyses the differences and deviations, resulting in professional reports. They are delivered as documents such as written reports, graphical models like drawings, CAD models and heatmaps and non-graphical information like lists, spreadsheets and calculations.”

He says all this information can be digitally managed within known construction management solutions. A unique selling point, however, is that BuildIT can use the Faro Tracer Laser Projector to project CAD geometry and analysis results from the digital world back to construction site.

“In most countries, there are rules and regulations on how and at what intervals gas and oil tanks must be analysed. It has never been easier to meet these requirements than now. Faro offers a complete, fast, highly accurate and reliable end-to-end workflow in which hardware and software are optimally coordinated,” he adds.

Due to Faro’s unique onsite registration, the Scene software registers individual scans in real-time while the Focus Laser Scanner is still capturing the tank facility. Leaving the site with a fully registered model provides certainty and the analysis in BuildIT Construction can begin immediately. This efficient workflow provides more comprehensive analytical reports in a dramatically shorter time, the spokesman explains.

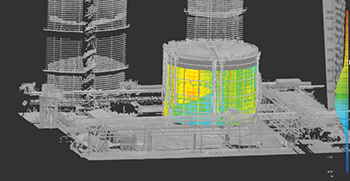

With BuildIT Construction 2019, a new series of tank analysis commands have been added to aid in identifying critical issues in the plant environment. These tools provide profound reports for better tank facility refurbishment decisions in the oil and gas industry. Because the results are so quickly available, they can be used on site to verify newly installed plants.

This process makes it extremely easy to fulfil legal requirements and documentation obligations. Existing condition analyses for preparations for maintenance, reconstruction or rebuilding are carried out much faster, more reliably and much more simply than before.

That gives clarity on the current situation for the facility manager and people running the plants and ensures confidence for plant renovation projects. The Faro workflow speeds up the design process of construction work.

BuildIT allows for features to be customised. The surfaces of the tanks can be unwrapped and analysed in a grid-based report, and the results can be displayed as full 3D heat maps. Horizontal deviations are analysed by automatic cuts through the tank in customisable intervals.

Definable automatic functions check the tank walls for vertical flatness and plumbness. Foundation settlings are verified and, of course, BuildIT also has Volume Computation (cut/fill).

The list of functions is quite comprehensive. Reporting follows much of the same way that American Petroleum Industry (API) standards call for. Results can not only be used for documentation but also provide the basis for further planning, for example, they can be directly transferred to Autodesk Plant 3D.

“Furthermore, Faro provides the only inclusive quality control field-to-finish workflow not only for the oil and gas but for the entire construction industry. Hardware and software components are optimally adjusted to each other.

“The combination of the Faro Focus Scanner with Faro Scene software enables the complete creation of scan projects consisting of hundreds of scans on site, without the need of further reworking in the office. The as-built data is transferred to BuildIT Construction on site, where it is compared against CAD models and analysed for deviations,” the spokesman says.

These reports are not only documented in a variety of ways, but they also serve as a basis for further planning and rework. Deviations and errors are detected at an early stage, corrected if necessary or considered in the further construction process.

BuildIT Construction can drive the Faro Tracer Laser Projector and use it to project CAD elements into reality. These projections are used not only in prefabrication to assemble components, but also on construction sites to mark areas outside defined tolerances and to visualise remedials.

This workflow is unique, new and fast. It is fast enough, to measure freshly poured concrete within minutes, for example, unevenness in formwork. This can save immense costs for reworking, he adds.