Alec raises bar with One Za’abeel

Alec Engineering and Contracting is showcasing its advanced engineering skills and its prowess at using 4D construction modelling in building One Za’abeel, which comprises two towers that flank a busy flyover in Dubai.

01 December 2019

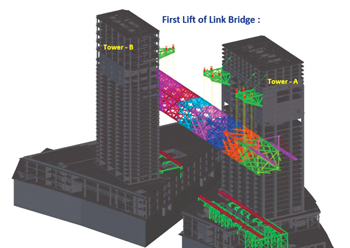

Dubai-based Alec Engineering and Contracting is pushing boundaries of engineering with its One Za’abeel project, which involves building the world’s largest cantilever at podium level and then raising it over 100 m to connect two towers that flank a busy flyover.

Located in central Dubai, One Za’abeel is a mixed-use development that features two towers (A and B) of 70 and 60 floors comprising The Linx, a panoramic sky concourse that connects the two towers, hotels, residences and offices. The project, being developed by Ithra Dubai, is worth $1 billion and will be built in four years.

The cantilever bridge of The Linx is 227 m in length and weighs a massive 8,500 tonnes of pure steel, making it heavier than the Eiffel Tower. It is being built in seven segments, with each fabricated offsite and then welded onsite at the podium level.

|

|

Computer models of the project showing the raised cantilever. |

The bridge is slid segment by segment (from Tower A to B) after each assembly. The third sliding was carried out just last month (November), marking a milestone for Alec. The second sliding was done in October. The first slide was for around a 25-m distance, with the total weight of the segment being 2,500 tonnes.

After all seven segments are completed and slid, the bridge will then be strand-jacked and lifted to its final position 105 m above ground level. A special crane has been imported from Australia for this purpose alone, Bayan Abdel Rahman, 4D planning specialist at Alec, tells ABDULAZIZ KHATTAK of Gulf Construction.

The main challenge, she says, is sliding the bridge over the busy flyover bridge, used by over 1,000 vehicles during peak hours. This required proper planning and time management as road closure is required, which needs approvals from local authorities, so Alec has to be very specific, she adds.

For the second slide, Alec requested road closure from 10 pm to 5 am – any changes to the plan would mean shifting the task to another day.

One Za’abeel will have a total built-up area of 5.8 million sq ft and a retail plaza. The development will have seven basement levels – featuring the deepest basement level in the UAE so far – and an infinity pool at 110 m built on top of the cantilever bridge. Some 70 elevators will allow for vertical transportation.

“The idea was to build an iconic project that connects old Dubai with new Dubai,” says Abdel Rahman.

Alec is the main contractor for One Za’abeel, which was designed by WSP and is being project managed by Mace. It also involves about 65 subcontractor packages, calling for close and effective coordination.

Abdel Rahman says with so many stakeholders involved and over 40,000 activities in an overall complex project – with many structures being constructed simultaneously – Alec has adopted a well-organised and innovative 4D plan, which has been implemented into all its projects.

Alec is focused on using the latest applications for proper planning, optimum resource utilisation, seamless communication, and cost saving. For the One Za’abeel, it chose Bentley Systems’ Synchro because it offers a very strong planning engine, in addition to its 4D modelling capabilities and compatibility with other modelling applications on the market.

With Synchro, Abdel Rahman says, a change in any sequence on the plan allows you to see the impact on the model directly. Thus, Alec can insert many scenarios to get optimum output results.

She says the project team first used traditional methods to build different scenarios, anticipate risks, and understand the full sequence of the project. However, the team required better visibility into the project and needed to streamline communication among all stakeholders.

“To meet these objectives, the project team implemented Bentley’s Synchro to create 4D models. The process specifically helped to determine installation scenarios for the flyover bridge,” she adds.

Synchro, she says, allows 4D information to be shared among all departments. In fact, a detailed 4D execution plan was created at the start of the project (in 2017) – to track and monitor all processes.

Using Synchro, Alec could test many scenarios to get the most constructible one, including highlighting areas that consumed the major cost. Synchro also allowed Alec to see time clashes.

Citing examples, Abdel Rahman says Synchro alerted that the first segment of the linking bridge was being assembled before the temporary bridge was erected; slabs were being poured while the temporary steel was still in place; and façade erection for the podium levels clashed with the temporary steel for the bridge. So Alec revised its plan accordingly.

Risk management was very much on mind. Abdel Rahman says the authorities were sceptical about the cantilever construction, moving it across a busy road and then lifting it 100 m above ground. However, Alec used Synchro’s output-risk management to put their apprehensions to rest.

In all, to date, Alec has saved over $16 million in costs and 65 days in time. This includes a saving of $12 million and 40 days solely by revising the location of the cranes in Synchro. Another saving was through the bridge sliding. Initially, seven slides were planned but this was revised to six, saving four weeks of time and $4 million. Productivity was increased by five per cent, she adds.

Alec Engineering and Contracting was one of 54 finalists Year in Infrastructure 2019 awards, shortlisted from amongst the 571 nominations submitted by more than 440 organisations in more than 60 countries - and only one of two from the GCC. It was nominated in the 4D Construction Modelling segment for its One Za’abeel project in Dubai.

This year, Alec is celebrating 20 years in the construction industry. The stalwart has undertaken numerous projects spanning various sectors, including 26 in airports, 23 hotels, 15 retail, eight commercial, seven residential, six leisure, three hospitals, and one educational project.

Its current projects include One Za’abeel, Conference and Exhibition Centre (COEX) Campus Package Expo 2020, Dubai Hills Mall, The Residences at Marina Gate, the Saudi Pavilion Expo 2020, Mobility Pavilion Expo 2020 (main contract) and the rollercoaster at Dubai Hills Mall, all in Dubai.

- Alec raises bar with One Za’abeel

- Honeywell wins major PRIZe automation deal

- Arabtec posts $119m net loss; revenue down 18pc

- Sparrows doubles size of UAE operations

- Archirodon secures big Adnoc EPC contract

- Eagle Hills appoints contractor for Kalba project

- News in brief