Adhesives hold key to flooring durability

01 April 2020

Modern floor coverings exposed to intensive pedestrian traffic, as in hospitals, showrooms and offices, have to meet a range of performance requirements in terms of resistance to abrasion, slip, impact, temperature change, water and cleaning agents, in addition to maintaining their aesthetics.

The durability and successful use of such floor coverings depends to a large extent on the flooring adhesives that are used to integrate the substrate with the floor covering.

Dammam-based Construction Material Chemical Industries (CMCI), a trusted supplier of high-quality construction chemicals, says it develops, manufactures and markets a range of adhesives for such applications.

|

|

Figure 2. |

The company’s adhesives are based on different chemistries – polyurethane, epoxy or acrylic – to suit the nature and type of floor covering, says S M Musabbar, Innovation Manager at CMCI.

“The surface profile of the floor covering also dictates the required consistency of the adhesive – that is, if the adhesive has to be in the liquid form or in the paste/thixotropic (caulking) consistency. For example, a caulking consistency is desirable for a parquet adhesive,” he explains. “In addition, industry standards stipulate the performance requirement of these adhesives in terms of peel strength, shear strength, dimensional stability, volatile organic compounds (VOC) content and emissions. The practising engineers and applicators define the extent of tackiness and grab the adhesive should have with PVC tiles/carpets, the required open time before laying the floor covering, and the ease of applying the adhesive.”

Among CMCI’s most popular flooring adhesives products is Acrobond vinyl adhesive, which was first introduced in 2016 and relaunched in 2019. This single-component water-based product is easy to apply and ready to use and has good wet and dry tack properties and peel strength. The Aramco-approved product is suitable for tropical (hot) climates.

“Thanks to its outstanding adhesive characteristics with various substrates and adherends, and due to its excellent cohesive strength, Acrobond vinyl adhesive has been successfully used to adhere several types of PVC floor coverings, such as PVC tiles and sheets, textile coverings, carpets, etc. These flexible floor coverings require the adhesive to be flexible, and dimensionally stable for long-term performance, especially when the floor covering is exposed to varying temperatures,” he says.

The high wet tack property of this adhesive, and fast curing (setting) properties enable the project stakeholders to carry out the flooring works on a fast track.

As an adhesive for flexible coverings, the peel strength and shear strength are of high importance and Acrobond vinyl adhesive is tested to meet these stringent requirements:

• Peel Strength (EN 1372 – adhesives – Test method for adhesives for floor and wall coverings – Peel test)

To conduct the peel test, Acrobond vinyl adhesive is applied over a fibre-cement board (150 mm x 50 mm) using a notched trowel and the PVC floor covering measuring 200 mm x 50 mm is placed – after 10 minutes and 30 minutes of open time – over the adhesive. The sheet was then pressed with a roller. The test specimens were stored for 14 days at 23 degrees C/50 per cent relative humidity. The peel strength was tested at a speed of 100 mm per minute.

The data in Figure 1 indicates the need to lay the floor covering well within the open time to achieve the best adhesion and performance.

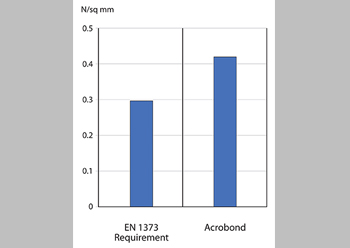

• To test the shear strength (EN 1373), the testing specimens measuring 60 mm x 50 mm were bonded using Acrobond vinyl adhesive and were stored for 14 days at 23 degrees C/50 per cent RH) .

The shear strength was tested at a speed of 20 mm per minute (Figure 2).

Acrobond vinyl adhesive was also tested to EN 14259 standard to ensure it meets the mechanical and electrical performance requirements for adhesives for floor coverings.

Apart from Acrobond vinyl adhesive, CMCI also manufactures a range of polyurethane adhesives for various applications. The company has recently launched a high-grip adhesive (Fix-It Fast) as a construction adhesive to fix various construction materials. Other products include Urekem AG2, a two-component, solvent-free, polyurethane (PU) adhesive used to fix artificial grass/turf over concrete; Urekem MCA, a single-component ready-to-use adhesive to fix EPS/XPS (expanded/extruded) foams on many substrates; Urekem LP 1561, a two-component PU with long pot-life is used to bond fibreglass to wood to EPS foam in container building industry.