The digital twin solution allows users to create a construction model that can be used for up-to-date 4D scheduling and simulation, quantity/estimation and cost management, and real-time field performance updates.

Digital twins hold key to smooth operations

Access to data and transforming it to knowledgeable information is an untapped opportunity at airports that can help all stakeholders, and the digital twin solution is an enabler of that opportunity, says ZUBRAN SOLAIMAN* of Bentley Systems.

01 July 2023

One of the biggest challenges in constructing airports is completing projects on time and within budget – a task that becomes more difficult when trying to minimise disruptions to schedules and the overall customer experience. However, new technology is now revolutionising work in this sector.

Digital twin solutions, especially those with 3D, 4D, and 5D capabilities, can significantly improve efficiency and reduce costs. Drones and mobile capture can also be used to conduct site surveys and monitor construction progress, which allows for more accurate planning and faster decision-making. Advanced communication technologies supported by Internet of Things (IoT) technology can also enable real-time collaboration between construction teams and airport operators, ensuring that the airport is designed to meet the needs of all stakeholders.

Overall, new technologies have the potential to improve the safety, efficiency and sustainability of airport construction.

Background

With over 80 million jobs and around $3.5 trillion in economic activities around the world, the aviation industry contributes well over 4.5 per cent of the global GDP. By 2040, airports in the Middle East are expected to handle 1.1 billion passengers – an increase of nearly 300 per cent from 2019.

According to Airports Council International (ACI), the capex in the Middle East is projected at about $151 billion between 2021 and 2040, with just under 60 per cent of this expenditure on greenfield airport projects in the near time (2021-2025).

|

|

Solaiman ... new technologies have the potential to improve the safety, efficiency, and sustainability of airport construction. |

The growth in passenger demand will, undoubtedly, increase pressure on the airports in four main areas:

• Ensuring that infrastructure is in place for the increased demand capacity;

• Ensuring excellent passenger experience;

• Delivering against environmentally sustainable targets, particularly decarbonisation goals;

• Delivering on time and on budget, and accelerating the commissioning of the project.

The success considerations are, therefore, clear: the design and construction of airports (greenfield or brownfield) must address the above-mentioned areas and function in perfect harmony to meet optimal delivery. Moreover, as airports are operational around the clock, construction activities must be carefully planned and coordinated to minimise disruption to the ongoing airport operations.

Airport owners and their supply chain are embracing smart technology, such as digital twins, to attain that goal, which is to meet the potential increase in passenger demand, accommodate the high aspirations on user experience, and adhere to sustainability credentials while delivering around an operational airport. Technology must also allow the complex ecosystem of stakeholders and their activities to be transparent, agile and responsive.

|

|

Digital Twin Project Data Flows |

Data – an untapped resource?

It is acknowledged that there is a huge volume of transactional, static and historical data of various formats, diversity, and maturity that exists and spans the entire lifecycle of the assets, processes, and systems within an airport campus.

Unsurprisingly, much of the data resides in siloed systems, and it is challenging to manage, access, validate and understand it. This often requires multiple applications, which can present the organisation and teams involved with IT headaches and add unforeseen costs to make sound and confident decisions. Transforming the data into valuable information is a key output in the solution. Typically, engineers and surveyors responsible for delivering new or maintaining existing infrastructure assets will be familiar with terms like building information modelling (BIM), construction simulation, geographic information systems (GIS), and 3D modelling. However, it can be like a foreign language for stakeholders such as lease or property managers and executives.

Similarly, IoT devices, which were useful for providing near or real-time updates on project status, asset conditions and performance, can now be correlated.

For example, if the number of passengers exceeds the humidity and temperature tolerance within a terminal or gate, this can be notified and action taken.

There is also a need for cross-lifecycle collaboration. For example, the operation and maintenance team can access real-time status updates from planned construction activities, or project planners have the latest brownfield asset information, location and condition.

In short, access to data and transforming it to knowledgeable information is an untapped opportunity at airports that can help all stakeholders, and the digital twin solution is an enabler of that opportunity.

What is a Digital Twin?

Many interpret the definition of a digital twin as a 3D model of a physical asset, for example, a terminal building, runway, bridge, or tunnel. However, without a connection between the digital version and its physical counterpart or process in the real world, it is a static update of an asset or activity at a given point in time.

Bentley defines a digital twin as a realistic and dynamic digital representation of a physical asset, process, or system in the built or natural world. The goal is to connect everyone and everything in the infrastructure engineering value chain and extended project ecosystem. To further enable owner-operators to understand the data, the information is also curated through proprietary machine learning, analytics and asset performance algorithms for a given stakeholder or process. By overlaying the engineering technology (ET), operations technology (OT), and information technology (IT), it enables users to visualise, query, and analyse infrastructure digital twins in their full context, at any level of granularity, at any scale, all geo-coordinated and fully searchable.

With the adoption of design modelling, coupled with brownfield information such as high-fidelity 3D reality models, a data-rich model can now be provided that becomes the start of a digital twin which can be leveraged downstream during construction and operations. In this representation, the digital twin is evergreen. It maintains and builds upon the data created, captured or ingested from enterprise systems in each project or asset lifecycle phase. In addition, the openness of the digital twin solution allows an efficient mechanism to apply seamless workflows with other applications.

For example, the design models can seamlessly calculate embodied carbon without manual data/file intervention. There is no lost or created data, making the entire process more transparent and efficient.

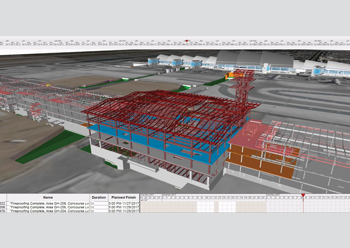

The solution can easily import design data, construction data, and field data. This allows users to create a construction model that can be used for up-to-date 4D scheduling and simulation, quantity/estimation and cost management, and real-time field performance updates.

With the construction model easily assembled by ingesting validated data from multiple sources, it becomes very easy to share with stakeholders from other departments in an intuitive 3D environment.

|

|

Construction 4D/5D Model Authoring |

Benefits of Digital Twins

Numerous benefits can be attained through collaboration and transparency. For instance, Sydney Airport reported savings on working time from one use case only, which was related to finding data and information faster. Studies also show that the digital twin can save at least nine per cent in the construction phase (five per cent reduction in construction cost and four per cent reduction in construction schedule). It is important to note that efficiencies are demonstrated and compounded throughout the life of the airport. In other words, continuously adding more workflows connected to a digital twin substantially compounds the return on investment. For example, the assets can be designed and tested in the early stages before construction begins. Here, multiple types of simulations can be run repeatedly to determine the best, most effective and most time-efficient outcomes without minimal transformation or duplication of data. Users can be confident that the simulation result is based on the latest and validated model.

The seamless ability to ascertain sustainability metrics, like embodied carbon, is a more efficient step toward sustainable construction. Assets can be designed and tested to ensure rigorous environmental stress tests and increase infrastructure resilience to ever-increasing extreme weather events. Any potential issues or delays can be addressed early in the project, allowing the owner-operator to determine the best, most cost-effective and time-efficient outcome.

The efficiencies gained also address maximising the limited workforce environment and the effective hand-over process to operations once the project is complete.

Ultimately, these technologies will improve the customer experience. It will also allow for greater project delivery and fewer disruptions to airport passengers during construction.

* Zubran Solaiman is Director of Product Portfolio for Smart Cities, Airports, Ports, Hospitals, and campuses, Bentley Systems.

Digital Twin Project Data Flows

Construction 4D/5D Model Authoring

- High-flying ambitions

- Digital twins hold key to smooth operations

- What is a Digital Twin?

- LEED-ing the way in sustainable construction

- Hangars address A380 wing cracking issue