Technal provided a unitised system that was able to accommodate both the glass and the GRFC system of the facade.

Unitised system stands test of time

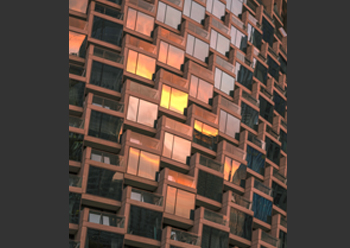

Burj Vista is more than just a pretty façade … its avante-garde design utilises a customised unitised system that combines a curtain-wall and GFRC cladding to provide unobstructed, front-row views of the iconic Burj Khalifa as well as protection from solar radiation.

01 October 2023

The award-winning Burj Vista continues to grab attention in Downtown Dubai, thanks to its avante-garde design that was created to provide tenants with unobstructed, front-row views of the iconic Burj Khalifa, the world’s tallest building.

The striking high-rise residential complex – previously known as the Grand Boulevard – was one of the first buildings in the UAE to utilise a unitised system that integrates different façade materials and was a trendsetter in terms of the sustainability features it incorporates, says Technal, a pioneering international specialist in architectural aluminium building systems.

Technal – part of the Norway-headquartered Hydro Group, a fully integrated aluminium company – provided a customised unitised system to accommodate the unique envelope of Burj Vista, which combines a curtain-wall and glassfibre-reinforced concrete (GFRC) cladding to respond to the stringent requirements of the project.

|

|

ASGG adopted a staggered configuration of observation rooms and terraces that offer unobstructed views while reducing the heat gain within Burj Vista. |

“Burj Vista stands as a pioneering structure in the UAE, having been one of the first to incorporate a unitised curtain-wall system. This marvel of engineering showcases the brilliance of the collaborative efforts between our technical team and Koltay Façades,” says Sami Zgheib, Technical Director at Technal (Hydro Building Systems Middle East).

“Together, we have crafted a bespoke solution that seamlessly integrates diverse materials into a single system. This innovative approach allows the curtain-wall to house both the glass and the GFRC, creating a modular system that envelopes the building, epitomising both beauty and technical ingenuity,” he adds.

Developed by Emaar Properties and designed by Adrian Smith + Gordon Gill (ASGG) Architecture, the two-tower complex – one 66 storeys high and the other 22 storeys – covers a total area of 400,000 sq m. The towering structures of Burj Vista, which were completed in 2018, play a significant role in the creation of a stunning urban amphitheatre plaza that also boasts high-end retail establishments.

The design of these towers presented a unique set of challenges, especially with the need to maximise the view of the Burj Khalifa in every unit while minimising energy consumption and ensuring the comfort of its occupants, says Technal.

To achieve this, the architects adopted a staggered configuration of observation rooms and exterior terraces that offer unobstructed views while also reducing the overall heat gain within the towers. The sloped glass exterior walls of the tower, coupled with the terraces, provide maximum shading and reduce wind-borne sand collection, making it ideal for the warm Dubai climate, it adds.

Additionally, the designers utilised high-performance coatings on the exterior glass and a significant amount of GFRC cladding systems to reduce the amount of glass, and oriented the towers to minimise solar exposure. These sustainable strategies, coupled with landscaped event areas and shaded paths, not only reduce energy consumption but also contribute to the distinctive identity of Burj Vista.

|

|

The facades of Burj Vista... designed with views to Burj Khalifa in mind. |

The key challenge in accommodating this design was to create one modular system for the entire envelope that included the curtain-wall and GRFC cladding – and the solution offered by Technal was a unitised system, customised to accommodate both these materials.

Technal’s solution comprised its Geode MX unitized curtain wall; Geode MX stick system and customised concealed Soleal PY doors.

“The challenge for Technal was to supply a unitised system that was both able to accommodate the glass and the GRFC system,” explains a spokesperson for Technal. “Therefore, the whole envelope was prefabricated, which allows for greater precision and speed in the manufacturing process. This means that construction time was reduced, as the installation of prefabricated facades on-site is typically quicker and easier than traditional construction methods.”

There are four main facades surfaces, each exposed to varying levels of high solar radiation and having varying views. In generating the plan’s geometry, the building that faces the Burj is maximised in length and therefore in façade area. This section of the facade was required to be protected from the sun, yet be open enough to provide views of the Burj.

ASGG adopted a number of strategies to address the design challenges and incorporated a number of sustainable elements in the building. A significant amount of GFRC cladding systems has been used to minimise the amount of glass. This solid material reduces the amount of solar radiation impacting the interior residential spaces, improving comfort levels and reducing energy use. It also reduces glare and improves thermal conductivity, according to the architects.

The south-facing walls of the building are clad with prefabricated, modular, locally produced GFRC.

GFRC is also used to clad the west-facing facade, where the low angle of incidence of the sun is more difficult to control. Narrow vertical glass openings placed deep into the GFRC passively reduce direct solar radiation.

The south, southeast, and southwest walls are designed to utilse mostly solid walls, with a glass ratio that optimises natural light and views, while controlling solar access into the units.

The areas with direct views to the Burj Khalifa are clad in glass and sloped toward the ground to reduce the angle of incidence and solar radiation, as well as the cooling load on the building. Here, the glazing features high-performance coatings.

The north and northwest walls are designed to receive more natural light and reduce the need for artificial light. The proportion of solid to glass walls is increased on these facades.

The northwest wall is designed to provide balcony areas that are shielded from the afternoon sun by using recessed glazing. A system of operable screens was conceived, which enables sweeping views during most of the day, while still protecting the interior spaces from strong solar radiation toward the end of the day.

These architectural decisions make Burj Vista’s design specific to its programme, location, and massing configuration, giving it a distinctive identity with high-performance characteristics.

These sustainable features have recently earned accolades for the building, namely the Green Good Design Awards from the Chicago Athenaeum, and the Citation of Merit for its self-shading balconies from AIA Chicago.

Burj Vista, designed as a sophisticated anchor presence on Dubai’s Boulevard, with the first two levels featuring high-end retail, offers an array of luxurious features, including high-end finishes in all interiors, a semi-protected lounge area with decorative water features that open up to a landscaped garden, indoor and outdoor pool, and convenient access to several prominent locations in Dubai such as Burj Khalifa, Dubai Mall, Burj Lake Promenade, World Trade Center, and Sheikh Zayed Road.