GRI scores well with prestigious landmarks

01 December 2023

Gulf Rubber Industries’s (GRI) pioneering efforts in developing environment-friendly rubber products and championing sustainability practices have propelled the Dubai-based company to the forefront of the industry, solidifying its position as a market leader in a sector that is increasingly embracing eco-friendly construction materials.

Its products are currently being utilised in a number of key projects in the Gulf region including the new Dewa headquarters, Cavalli Couture and Uptown Tower in Dubai, UAE.

Of particular environmental interest is the Dewa headquarters, designed to be a LEED Platinum project, which will be the tallest, largest, and smartest net-zero government building in the world.

“This project has the highest level of sustainability requirements. All the products developed by GRI for this project are in compliance of the specifications,” Urfi Kidwai, Managing Director of GRI, tells Gulf Construction.

GRI was also involved in some of the recently completed landmark developments including the Museum of the Future and One Zabeel.

“The Museum of the Future is one of the most iconic buildings on Earth. The building envelope consists of nearly 1,024 panels that had to be individually moulded and manufactured. Our main challenge was to develop gaskets for the complete façade. Initially, the façade had 11 different gaskets which were brought down to only two silicone profiles for the complete façade,” he explains.

|

|

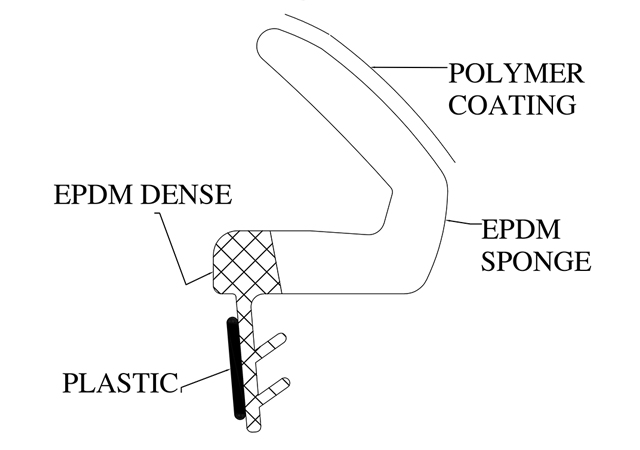

GRI’s latest innovations is the triple extrusion polymer-coated profile. |

Another prestigious project was One Zabeel, which has a suspended bridge linking the two towers together. The bridge is suspended at 100 m above the ground, making it the world’s largest cantilever. GRI has developed and supplied silicone gaskets for this project, he says.

Apart from its domestic market, GRI has carved a niche for itself in the global market thanks to the quality of its products. The company currently exports 55 to 60 per cent of its output, with its products destined for the entire GCC, North America, Canada, Germany and France.

In the US, some of its key ongoing projects include the YouTube headquarters, 3050 Aventura, Academic Tower, 100 Queens Quay, 520 Fifth Avenue and One Journal.

GRI continues to expand its global reach by approaching new markets with the aim of increasing its export volumes to 70 per cent.

“We have a plan to expand our production facility to increase the production capacity by 30 per cent and boost the export volumes by 15-20 per cent,” Kidwai reveals.

GRI has been a leading manufacturer of rubber products in the region for many years. Kidwai attributes its success to a number of factors including:

• Quality products: Consistently producing high-quality rubber products that meet customer needs and industry standards. It also maintains strict quality control procedures to ensure that its rubber products meet or exceed industry standards and regulations;

• Innovation: Investing in research and development to create innovative rubber solutions and stay competitive;

• Skilled workforce: Having a skilled and experienced workforce that ensures efficient production and quality control;

• Customer focus: Maintaining a strong customer-centric approach and building lasting relationships with clients;

• Strong management: Effective leadership and strategic management that guides the company’s growth and sustainability;

• Market presence: Expanding market presence regionally or globally to tap into new opportunities;

• Adaptability: Being adaptable to changing market demands and technological advancements in the rubber industry;

• Sustainability: Implementing eco-friendly practices and sustainability initiatives to meet environmental standards;

• Continuous improvement: A commitment to continuous improvement in processes, products, and operations; and

• Competitive pricing: Offering competitive pricing to attract and retain customers.

GRI says it offers complete solutions of different products for various industries. These comprise EPDM, silicone and neoprene rubber profiles; dual durometer profiles; EPDM sponge profiles; polymer-coated profiles; EPDM, silicone and plastic mouldings; and rubber fenders, bumpers, corner guards and wall guards.

In line with its innovation focus, the GRI team has developed an innovation strategy by involving the management team in line with overall GRI’s focus on operational excellence and stakeholders’ satisfaction,says Kidwai.

Among its latest innovations is the triple extrusion polymer-coated profile, a unique product for the windows and doors industry.

Elaborating on the product, he says: “Generally, it is a challenge to bond plastic with EPDM. Through our extensive research and experience, we have developed our own in-house compound formulation and special machines by which the bonding of plastic with EPDM is made possible.

“This is big achievement for GRI to prove its commitment towards innovations and achieving excellence.”

Contributing towards environmental sustainability, GRI has installed solar panels on the roof of its facilities which generate around 40 per cent of its energy requirements. The company says it has also implemented processes to monitor the air and water quality.

“All the processes and operations are audited and governed by the local authorities and it is our top priority to maintain health and safety procedures. In addition, GRI has been contributing to various programmes to promote and exchange different cultures within the UAE and encourages its workforce to practise and maintain a work-life balance,” he says.

GRI continuously monitors market trends and customer demands to identify emerging opportunities and adapt product offerings accordingly. It also collaborates with construction companies, architects, and engineers to understand their evolving requirements and co-create solutions that address specific challenges.

In addition, the company employs flexible manufacturing processes that can quickly adapt to changing customer demands and market trends.

“By combining these strategies, Gulf Rubber Industries can position itself as a forward-thinking and adaptable player in the construction industry, allowing it to anticipate and meet the evolving needs of its customers and the market,” he says.

“As a part of the ongoing commitment to excellence, Gulf Rubber Industries has been recognised with the most prestigious ‘Sheikh Khalifa Excellence Award (SKEA)’, Appreciation for 2017-2018; ‘Sheikh Khalifa Excellence Award (SKEA)’, Silver category in Manufacturing for 2019-2020; Dubai Quality Appreciation Award (DQAA) for 2020; and Mohammed bin Rashid Al Maktoum Business Award (MRMBA) in 2021; and Sharjah Small & Medium Enterprises Award (SjhSeen) for 2022 for its distinguished efforts and commitment to quality as an ideal approach towards achieving business excellence,” he concludes.

- GRI scores well with prestigious landmarks

- Bobcat forklifts enter logistics market

- Geberit ONE melds design with function

- UAE debut for Volvo CE electric machines

- Hansgrohe focuses on sustainability

- Al Jazera uses CDE unit for City of Roses work