Energy-efficiency need of the hour: AHRI

Gulf Construction’s BINA GOVEAS speaks to Air-Conditioning, Heating, and Refrigeration Institute’s (AHRI) Managing Director Nabil Shahin about key issues in the HVAC sector ranging from trends and how smart technology is impacting the industry to the importance of adopting energy-efficient systems.

01 April 2024

The recent COP28 UN Climate Change Conference held in Dubai, UAE, marked a significant milestone in the fight against climate change. A landmark agreement, the Cooling Pledge, was signed by 63 countries, including the UAE. This ambitious initiative aims to slash energy consumption of HVAC equipment by 50 per cent within the next decade, Nabil Shahin, the Dubai-based Managing Director of Air-Conditioning, Heating, and Refrigeration Institute (AHRI), tells Gulf Construction in an exclusive interview.

In addition to climate change, this push for energy efficiency is driven by a critical need. The Middle East is projected to experience a surge in HVAC equipment installation due to population growth and urbanisation.

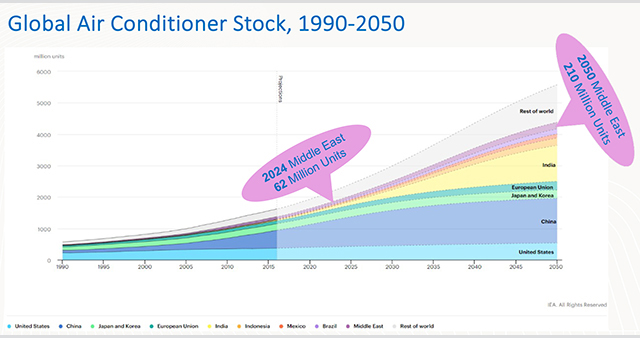

Quoting figures released by the International Energy Agency (IEA), he says: “The Middle East is projected to have three-and-a-half times more HVAC equipment installed by 2050 compared to the present day, driven by middle-class growth, urbanisation, and migration to the region. Future regulations will likely include limits on carbon emissions, with the HVAC industry being a significant contributor due to its high consumption of electricity, which relies on fossil fuels. Therefore, reducing the energy consumption of HVAC systems will be crucial in reducing carbon emissions.”

Due to the growth in population and construction, the number of air-conditioning units installed in buildings is projected to increase from 62 million today to 210 million by 2050, he elaborates (see graph above). The higher cost of efficient equipment and relatively low electricity costs in this region does have an impact on the demand for more energy-saving units.

|

|

Nabil Shahin |

The good news is that solutions are being developed. Organisations like the American Society of Heating, Refrigerating and Air-Conditioning Engineers (Ashrae) and AHRI are creating new standards to measure the total carbon footprint of buildings and equipment – not just energy consumption. This will empower consumers to make informed choices that benefit both their wallets and the planet.

However, while various organisations, advisory groups, developers, and financial institutions are working together to develop strategies to achieve this target, the government cannot achieve this goal alone and must rely on the private sector for support, he points out.

To do this, greater awareness needs to be created about HVAC technology in general, as well as the benefits of using energy-efficient technologies, Shahin points out.

AHRI is playing a major role in not only creating awareness, but also helping developing standards such as the SEER (Seasonal Energy Efficiency Ratio)-related standards that will be ready by the end of the year and upskilling technicians in the sector. It participates in most of the HVAC standards committees in the region and actively advises on the best standards to use, as well as the latest technologies and MEPS (Minimum Energy Performance Standards) levels that are suited for this region. AHRI also chairs the Gulf Standardization Organization’s (GSO) technical committee on air-conditioning.

AHRI has a technology institute (AHRTI) that conducts research on emerging technologies, energy efficiency, indoor air quality, and refrigerants.

Excerpts of the interview with Nabil Shahin:

What are the most significant emerging trends in the HVAC sector?

District cooling, Variable Refrigerant Flow (VRF) systems, and inverter technology are at the forefront of the latest developments. District cooling, known for its efficiency, is expanding its market share, potentially transitioning into a utility service in the future. VRF systems, with their versatility of having multiple installation options and energy-saving capabilities, are gaining popularity among engineering consultants and developers. Additionally, consumers are becoming more knowledgeable about the improved energy efficiency of inverter technology, which uses variable speed motors that are replacing traditional fixed-speed, less-efficient motors.

|

|

|

How is the increasing focus on energy efficiency shaping product development and consumer choices within the HVAC industry?

Most of the HVAC equipment is selected by or sold to professional installers or contractors. Consumers usually have very little say on equipment selection. While more energy-efficient products are entering the market, end-user adoption remains somewhat limited to the entry level models that are barely above the MEPS established by the local governments. This is mainly due to the higher cost of efficient equipment and relatively low electricity costs in this region. Marketing efforts, education and raising awareness about HVAC technology in general, as well as the benefits of using energy-efficient technologies, are needed to bridge the gap.

How can the construction industry leverage design practices and material selection to promote energy-efficient HVAC system integration in buildings?

Design and MEP engineers have to pay meticulous attention to building envelope, where, for example, proper insulation and reflective material are utilised, and selecting energy-efficient certified equipment verified by third parties to ensure high building efficiency. These are essential components of this strategy. Also,there are software tools available that can accurately calculate the cooling load required and demonstrate the potential energy savings that will be realised by using different construction material, elements, designs, or HVAC equipment.

How are evolving regulations and standards shaping the development and adoption of energy-efficient HVAC technologies?

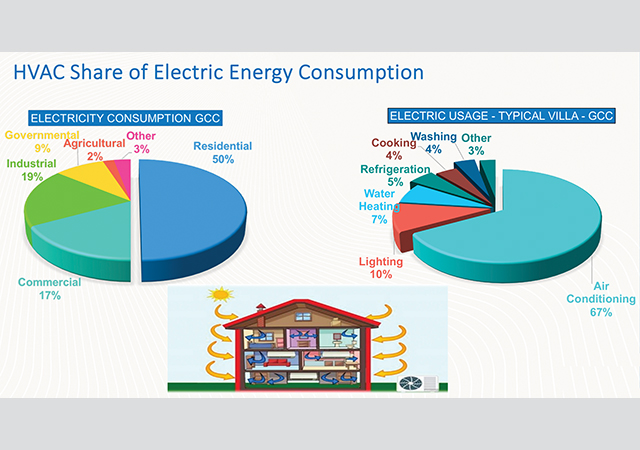

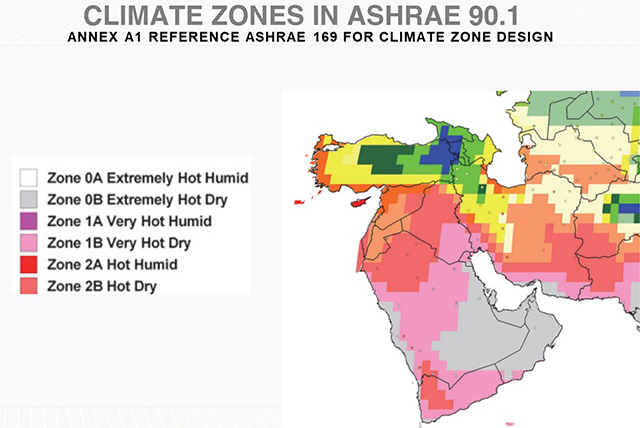

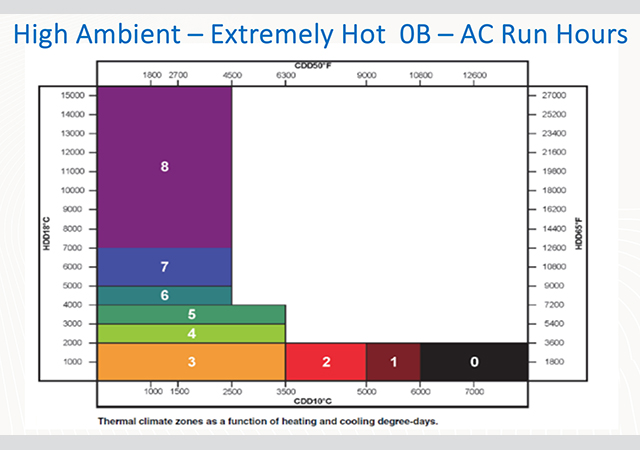

Due to high outdoor temperatures, electricity consumption of HVAC equipment can be very high in the GCC region. It can account for up to 70 per cent of the total electric consumption or bill in the residential sector. Air-conditioners can run for over 6,000 hours per year in the GCC. Manufacturers and regulatory bodies recognise this as a major area of concern, prompting manufacturers to offer technologies that save energy and governments to restrict the sale of inefficient equipment by establishing minimum limits. Governments are now exploring better methods to measure energy consumption of air-conditioning equipment. They have recently requested AHRI to develop standards that will calculate SEER for high ambient regions using their Mena standards technical committee, established specifically to formulate HVAC standards that are tailored for this region. The SEER-related standards will be ready by the end of the year and then adopted by the regional regulatory bodies.

|

|

|

How is the Internet of Things (IoT) transforming the HVAC sector, particularly regarding remote monitoring, control, and data analysis?

Data collection and analysis are becoming increasingly popular, and companies like Microsoft are getting involved. Simply put, data is important and if analysed can help save energy. For example, installing or using existing sensors to monitor a building can reveal a lot of clues on how to improve building efficiency by simple modifications or adjustments to building structure controls, components, or equipment. Some HVAC companies are now transforming into complete solution providers instead of just equipment sellers; they sell equipment, provide service and maintenance, and ensure continuous remote monitoring and energy savings through IoT.

What are the potential benefits and challenges associated with the integration of IoT technologies in smart heating and cooling systems?

While IoT technologies offer a big potential for improving HVAC efficiency, companies face significant hurdles such as explaining their benefits to the end-users and demonstrating the return on investment. This often requires conducting proof of concept exercises to showcase the benefits. The establishment of Energy Services Companies (ESCOs) has played a crucial role in providing examples of successful projects, further encouraging adoption and investment in IoT technologies that target energy savings.

|

|

|

In what ways are smart heating and cooling systems contributing to improved energy efficiency and occupant comfort?

Smart controls that use advanced features like learning algorithms, remote access capabilities, humidity and occupancy sensors and integration with smart home systems can improve energy efficiency and provide more comfort. These thermostats can optimise energy usage by learning occupants’ preferences or habits, occupancy and adjusting temperature and humidity levels accordingly, they allow for remote monitoring and control by connecting to smartphone apps or web interfaces and service or energy saving companies. They can also provide predictive maintenance where they would detect if the unit is experiencing issues or will have failures and alert the service company.

What resources and guidelines does AHRI offer to construction professionals in selecting appropriate and efficient HVAC equipment for new and existing structures?

AHRI has certification programmes for most of the major HVAC equipment used in residential and commercial buildings. Certification ensures that the product sold in the market matches the catalogue data of the manufacturer and complies with the regulatory requirements. AHRI conducts annual surveillance by randomly selecting and testing its certified products. Its certified product directory contains over seven million certified models. AHRI standards and certification programmes are trusted and used by most professional engineers and regulatory authorities. For instance, AHRI 1230 is the only internationally recognised VRF performance measurement standard that construction professional use to verify the equipment that they are planning to use; it includes provisions to test for high ambient conditions or 46 deg C for products installed in the GCC region.

How is AHRI addressing the growing demand for skilled labour in the HVAC industry in light of technological advancements?

Unfortunately, unlike in the US or Europe, HVAC technicians in this region are not required to be certified to service or maintain HVAC equipment. If such equipment is installed or serviced by an untrained technician, it can lead to various issues, including lower capacity and energy efficiency, failures and cause environmental and safety concerns related to refrigerant handling. Therefore, having certified technicians is crucial. AHRI members developed a technician training and certification programme under NATE (North American Technician Excellence) that can be utilised and is currently being tailored for this region.

Does AHRI actively engage with policymakers and regulatory bodies to advocate for standards that promote sustainable practices in the HVAC industry?

AHRI participates in most of the HVAC standards committees in the region and actively advises on the best standards to use, as well as the latest technologies and MEPS levels that are suited for this region. AHRI also chairs the Gulf Standardization Organization’s (GSO) technical committee on air-conditioning. The GSO, which aims to harmonise standards in the GCC region, develops various safety and performance standards that are adopted by many member countries. The HVAC standards currently under development will be launched this year and will be available for adoption by the member countries.

How does AHRI advocate for sustainable practices within the HVAC industry?

AHRI is the trade association representing all major international manufacturers of heating, water heating, ventilation, air-conditioning, commercial refrigeration (HVACR), and water heating equipment. It advocates for energy efficiency without favouring specific technologies or products, promoting a holistic approach to sustainability. We strive to be the leading, recognised, indispensable voice in the development of environmental and energy policy impacting our industry.

What initiatives or programmes does AHRI offer to raise awareness about energy-efficient HVAC solutions among consumers and industry professionals?

AHRI has a technology institute (AHRTI) that conducts research on emerging technologies, energy efficiency, indoor air quality, and refrigerants. For example, AHRI and UNEP worked on PRAHA, a joint project that focused on promoting low-GWP (Global Warming Potential) refrigerants for air-conditioning sectors in high ambient temperature countries like the GCC. This initiative focused on studying alternative refrigerants and evaluated them for energy efficiency, technical issues, sustainability, and economics.

What is AHRI’s perspective on the future of the HVAC sector, considering the combined influence of sustainability, technological innovation, and consumer behaviour?

According to the International Energy Agency, the Middle East is projected to have three-and-a-half times more HVAC equipment installed by 2050 compared to the present day, driven by middle-class growth, urbanisation, and migration to the region. Future regulations will likely include limits on carbon emissions, with the HVAC industry being a significant contributor due to its high consumption of electricity, which relies on fossil fuels. Therefore, reducing the energy consumption of HVAC systems will be crucial in reducing carbon emissions. Currently, standards are being developed by organisations like Ashrae and AHRI to measure embedded and operational carbon in buildings and equipment, slated for release by 2026. This necessitates the development of technology not only to demonstrate a product’s energy efficiency but also to convince consumers that it reduces carbon emissions.

Anything else you would like to add about the HVAC sector in the region?

During the recent COP 28 United Nations conference on the environment that was held in Dubai, The Cooling Pledge agreement was established and ratified by 63 countries, including the UAE. This agreement requires the participating countries to improve HVAC equipment energy efficiency minimums by 50 per cent by 2030 compared to 2021 levels. As part of the UAE’s second Nationally Determined Contribution (NDC) to the United Nations, Dubai has set a target to retrofit 30,000 buildings in the emirate by 2030. Ras Al Khaimah’s Retrofit Programmr aims to retrofit 3,000 buildings by 2040 to enhance their energy efficiency. Several hundred buildings have been retrofitted already by ESCOs and developers. However, the remaining balance of this target raises questions regarding implementation and financing. Various organisations, advisory groups, developers, and financial institutions are working together to develop strategies to achieve this target. It is evident that the government cannot achieve this goal alone and must rely on the private sector for support.

- Energy-efficiency need of the hour: AHRI

- Humidification systems can address IAQ challenges

- LG-Shaker factory gets VRF technology