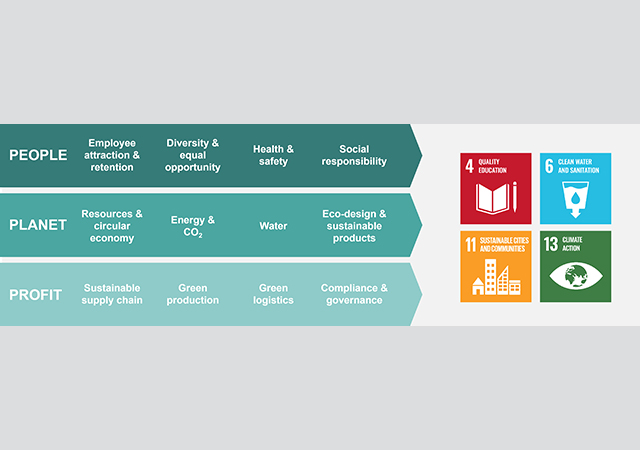

Figure 1. Four of the UN Sustainable Development Goals (SDGs) are particularly important to Geberit ... Goals 4, 6, 11 and 13.

Geberit prioritises environmental impact

Sustainable construction is crucial, as buildings account for over a third of global CO2 emissions, says Geberit. Here, the leading European sanitary solutions provider highlights its achievements in enhancing the environmental credentials of both its products and processes.

01 August 2024

Worldwide, over one-third of all CO2 emissions come from the construction and operation of buildings. That's why the construction industry is looking for solutions to make buildings more sustainable.

A sustainable building, for example, consists of materials that are long lasting, already recycled or recyclable. It saves space and resources. Moreover, sustainable construction promotes the transition to environmentally friendly mobility and the well-being of residents. Energy Efficiency and the use of renewable energy are important measures.

However, they are not enough on their own.

Saving water is also an important component of sustainable construction, because water is a scarce resource. This is where Geberit’s core expertise lies. For decades, we've been developing sanitary systems that are particularly durable, that help save water, that can be updated at any time, and they save space and materials based on the principle that each new product should be environmentally better than its predecessor, from piping systems to installation and flushing systems to our bathroom systems.

Geberit optimises the products and their production based on environmental and social criteria. This is evidenced by external evaluations. The transparent environmental product declarations of Geberit products help builders, architects, installers and customers make environmentally conscious decisions. This way we can contribute to sustainable construction.

Geberit drew up its first environmental strategy and implemented specific measures back in 1990. Over the years, this strategy was gradually expanded into a comprehensive sustainability strategy. Today, it is an integral part of the corporate culture. The strategy takes equal account of social, ecological and economic aspects. It is based on a total of 12 modules. These include: Employee recruitment and retention, diversity and equal opportunities, occupational health and safety, social responsibility, resources and circular economy, energy and CO2, water, eco-design and sustainable products as well as sustainable supply chain, green production, green logistics and compliance & governance.

Geberit’s sustainability strategy makes an important contribution to the United Nations' Sustainable Development Goals, which were adopted in 2015 as part of the 2030 Agenda. This involves 17 goals (known as SDGs, Sustainable Development Goals) that are to be implemented by the states – with significant support from the private sector – by 2030.

Four goals are particularly important to Geberit.

• Goal 4: "Inclusive and equitable quality education";

• Goal 6: "Access to safe drinking water and basic sanitation";

• Goal 11: "Sustainable cities and communities";

• Goal 13: "Measures to combat climate change".

Environmental performance in 2023

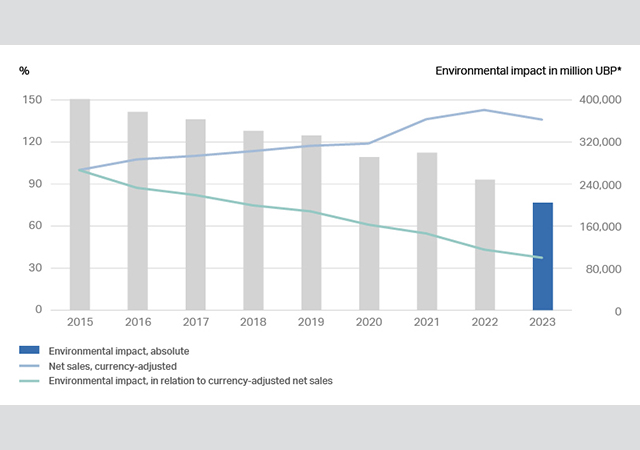

To measure its environmental performance, Geberit has been using the Swiss eco-balance method (see separate article) of ecological scarcity for many years, which takes into account a broad spectrum of environmental impacts (emissions, resources, waste) and summarises these in a key figure (see Figure 1).

• The Geberit Group's absolute environmental impact decreased by 17.6 per cent in 2023.

• Currency-adjusted net sales also decreased by 4.8 per cent in the same period, which is why the environmental impact in relation to currency-adjusted net sales (eco-efficiency) fell by 13.4 per cent.

• Since the integration of energy-intensive ceramics production in 2015, eco-efficiency has improved by 62.6 per cent.

• In terms of the long-term target value, which is based on an average improvement of five per cent per year, Geberit is, therefore, still very much on track (see Figure 2).

|

|

Figure 2. * UBP = Eco-points in accordance with the Swiss Ecological Scarcity Method (version 2021) |

On the path towards reducing CO2 emissions

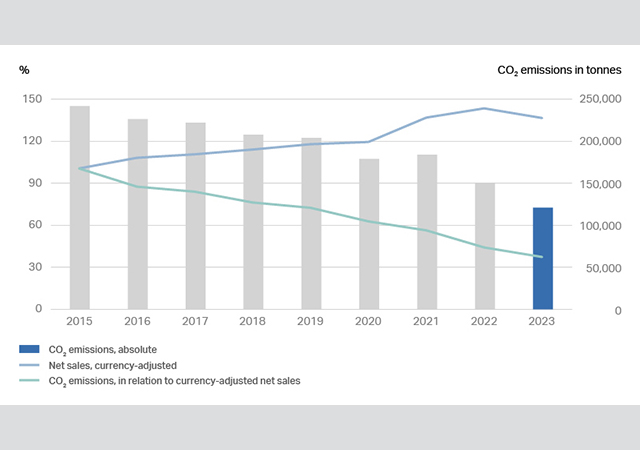

The Geberit Group stands for an ambitious and implementation-orientated approach in its activities. This also applies to the reduction of energy consumption and CO2 emissions. The central elements in the CO2 strategy introduced in 2022 are its integration into all relevant business processes as well as the handling of CO2 emissions as external costs by means of an internal CO2 reference price.

With the CO2 strategy, Geberit’s medium-term goal is a CO2 reduction of five per cent per year compared to currency-adjusted net sales, which would correspond to an 80 per cent reduction in relative CO2 emissions by 2035 compared to the reference year 2015.

Key figures 2023 and targets:

• Compared to the previous year, absolute CO2 emissions fell by 19.6 per cent to 121,014 tonnes.

• In relation to currency-adjusted net sales, CO2 emissions fell by 15.6 per cent. This means that the medium-term target set as part of the CO2 strategy of reducing CO2 emissions by five per cent annually was clearly exceeded.

• Since the acquisition of the energy-intensive ceramics production in 2015, CO2 emissions in relation to currency-adjusted net sales (CO2 intensity) have been reduced by 63.2 per cent (see Figure 3).

|

|

Figure 3 |

Share of renewable energies further expanded

The share of renewable energies is being further expanded throughout the company, always taking into account the internal CO2 reference price and the economic viability of the planned projects. Various means are available for this purpose: Purchasing green electricity with proof of origin, long-term power purchase agreements (PPAs) with selected plant operators or installing its own photovoltaic systems on the roofs of the production plants to generate electricity for its own use.

Key figures 2023 and targets:

• In 2023, the purchase of green electricity was increased by 16.5 GWh to 128.3 GWh.

• Overall, the share of renewable energy sources in electricity was thus 78.9 per cent (previous year 71.3 per cent).

Focus on water consumption

Careful, sparing use of water as a valuable resource is one of Geberit’s core areas of focus. The consistent focus on reducing water consumption, both in production and in the product use phase, is the company’s greatest lever for contributing to sustainable development. Geberit consistently applies measures to successively reduce water consumption. In particular, this includes measures such as reusing water in laboratories and the production process. At around 80 per cent, ceramic production accounts for the biggest share of water consumption.

Key figures 2023 and targets:

• In 2023, water consumption in production totalled 850,178 cu m (previous year 908,407 cu m).

• In comparison with 2015, the year of the integration of the ceramics business, water consumption fell by 27.4 per cent.

• Water consumption in ceramic production has been reduced by 30.6 per cent since 2015.

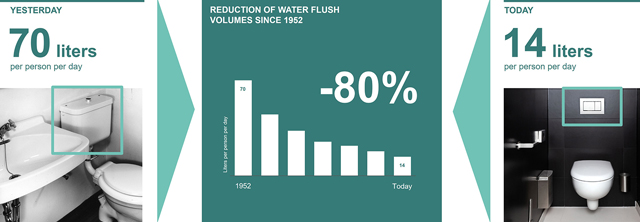

With eco-design, the products are also checked and improved with regard to water consumption. Geberit’s innovative sanitary products help to systematically optimise water consumption in buildings. According to a model calculation, water consumption for toilet flushing, for example, has decreased since 1952 by around 80 per cent from 70 litres to 14 litres per person per day thanks to several innovations such as flush-stop cisterns and Geberit dual flush (see Figure 4).

|

|

Figure 4. |

Occupational health and safety

Occupational health and safety has a very high priority within the Geberit Group. The number and severity of accidents are to be halved by 2025 based on the reference year 2015. The AFR (Accident Frequency Rate) is to be reduced to a rate of 5.5 occupational accidents (with absences of one day or more) per million working hours. The ASR (Accident Severity Rate) is to be reduced to below 90 days lost per million working hours.

All production plants and the central logistics centre in Pfullendorf, Germany, are certified in accordance with the ISO 45001 standard for occupational health and safety.

Key figures on occupational health and safety:

• In 2023, the accident frequency rate fell to a value of 7.3 (previous year 8.2), which corresponds to a reduction of 11 per cent.

• The accident severity decreased by 24.0 per cent to 119.7 (previous year 157.5) in the same period. There were no fatal accidents.

• Since 2015, the AFR has fallen by 36.0 per cent and the ASR by 41.9 per cent.

• Diverse vitality programmes are offered at 18 production and sales sites in the fields of exercise, mental fitness, nutrition and the working environment. The most comprehensive programme in this respect – “Geberit Vital” – can be accessed by around 40 per cent of the workforce.