3D printing has major potential in oil and gas industry: report

DUBAI, November 14, 2019

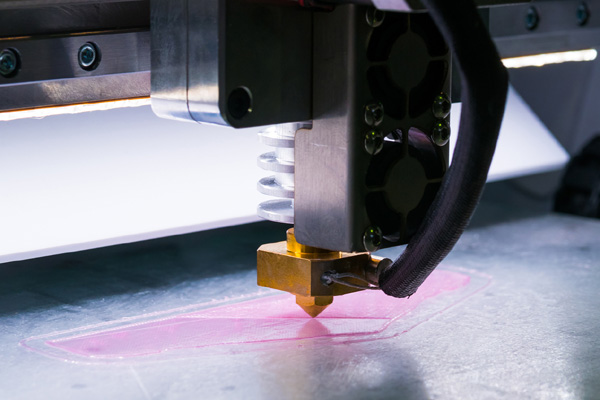

3D printing has tremendous potential in the oil and gas industry in delivering productivity gains, according to a report by GlobalData, a leading data and analytics company.

GlobalData’s latest report, ‘3D Printing in Oil & Gas - Thematic Research’, reveals that the technology is expected to gain further market penetration and find new use cases with greater collaboration between industry and technology players in developing more purpose-built 3D printing materials and solutions.

There is an aspiration to change the terminology around 3D printing to move beyond prototyping and think in terms of bigger volumes. The disruption in value chain means wider thinking, more in terms of digital manufacturing than 3D printing. Also, the wider idea of digitally manufacturing parts offers potentially much greater commercial success.

The global focus on climate change and global warming are driving a greater sustainability focus, based on the idea of creating a circular economy around 3D printing instead of a linear one.

It means keeping materials in use for the longest period of time at their highest available value.

By utilising changes in design –and cutting out unnecessary parts –the weight of parts created can be reduced by over 93 per cent in some cases, meaning a reduction in carbon footprint of up to 95 per cent, said the report.

The entry of several chemical companies such as BASF into the 3D printing market is helping drive the use of new innovative materials and compounds. Materials currently in use include glass fibre and diamond-based polymer composites, as well as plastic powders, plastic filaments, photopolymers, hydrogel, metals, ceramics, and biomaterials.

Early in 2019, T&R Biofab registered a patent for its 3D bioprinting technology to create artificial skin.

A digital twin provides a holistic view of the capabilities of an asset, helping to orchestrate, manipulate or program certain aspects of an industrial internet device.

In 3D printing, a digital twins’ advanced analytics will enable organisations to close the loop between a digital production plan and its actual performance. For example, Siemens’ MindSphere software interrogates an industrial internet data pool to feed insights back into the digital twin of a multi-jet fusion process, enabling an organisation to troubleshoot what happens before and after printing with equipment, material flow and worker performance.

3D printing has the potential to remove many of the constraints of the traditional manufacturing process. Unshackled from traditional manufacturing constraints, designers will be able to create geometries that better achieve their desired performance and meet customer needs.

GE took advantage of this freedom to redesign the LEAP jet engine nozzle from 18 separate components to a single part. This decreased the product’s weight and increased its performance with complex internal pathways.

The process of 3D printing is opening up new possibilities in other scientific areas. A recently 3D-printed model of a lung-mimicking air sac was created in the US, which featured functioning airways capable of delivering oxygen to surrounding blood vessels. The approach used in this project could open up the possibility of creating a new means of bioprinting human organs for transplant.

The need to better understand the industrial automation and materials world is driving more partnerships. HP, for example, is keen to learn from Siemens’ industrial automation expertise and BASF’s 3D printing materials specialism. It is also working closely with GKN in the same materials arena. Other alliances include Stratasys with Solvay, BASF with Impossible Objects, and French chemicals company Arkema with Carbon.

Asia is a fast-growing market for 3D printing and governments that might previously have invested in 3D machine manufacturing are now looking to stimulate 3D printing consultancy and co-creation.

3D printing company Materialise is helping manufacturing organisations in Ulsanin, South Korea, to develop applications through co-creation projects. Meanwhile, the German multinational Thyssenkrupp has argued that the 3D printing industry could generate an incremental value of $100bn by 2025 for the Association of Southeast Asian Nations (ASEAN).

Although there is a strong move towards greater adoption of metal 3D printing, materials manufacturers, including an increasing number of chemicals companies, are starting to produce a variety of new powders, including polymers. That will also be driven by an expected rise in manufacturing applications, rather than prototyping ones.

As organisations start to integrate 3D printing into their production options, there is a need to improve productivity, which means greater automation of tasks. Software will be key in achieving this, and incorporating simulation into 3D printing workflow can help reduce cost elements such as consumables and machine time. Simulating the 3D print process can make it easier for production operators to spot potential errors before a build starts.

This mirrors one of the continual arguments within the IT industry: the need for greater interoperability and technology-neutral solutions rather than proprietary ones. There is an ongoing argument that if the 3D printing industry is serious about getting industrial manufacturers to consider 3D printing as a valid manufacturing technology for final products, then tying industry’s hands by locking them into proprietary solutions that limit flexibility and choice may not be the best way to go, added the report. – TradeArabia News Service