T Nagadi boosts production capacity

01 September 2014

T NAGADI Preformed Concrete Factory currently has manufacturing facilities in Riyadh and Yanbu and the company now plans to further expand and cash in on an infrastructure boom under way in the kingdom.

The manufacturer will also roll new products as part of its growth strategy.

Over decades, T Nagadi has grown from a relatively small precast concrete plant in Riyadh to become one of the largest Middle East providers of concrete pipes and manholes and box culverts for storm water and sewage projects.

Although the owner Tarik Nagadi started his drycast concrete vibration business in Riyadh, where the demand for the concrete pipes and manhole products has traditionally been high, his sights from the very outset were focused on new developments which were destined to take place in the Western region.

“The lack of infrastructure in the region around Jeddah and the planned cities at Rabigh were obvious target markets.

Now, with T Nagadi’s new plant in Yanbu which covers an area of 200,000 sq m and has easy access to the main highway, the manufacturer is well placed to serve the Western region’s infrastructure growth with key quality products.

|

|

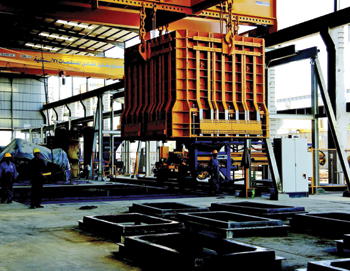

T Nagadi ... makes pipes up to 3,600 mm in diameter. |

But it is not just the Western region alone which T Nagadi has set its sights on, as the owner sees the entire kingdom and the rest of the GCC ripe for business.

With its Riyadh facility run out of space, T Nagadi has now decided to move to a much larger factory on the outskirts of the city, where it will pursue its expansion plans.

The current facility in Riyadh cannot be expanded further. However, with Saudi Arabia’s future requirements in mind, Tarik Nagadi has astutely procured over 150,000 sq m of industrial land near Al Kharj and will relocate the Riyadh factory over the next 12 months.

In addition, T Nagadi will procure more sophisticated and modern machinery with high output capacities to meet the demand of infrastructure developments in Saudi Arabia and the GCC. The Yanbu factory has room for expansion depending on demand.

T Nagadi currently manufactures concrete pipes in dimensions of 300 to 3,600 mm with and without lining for open trench and micro-tunnelling, lined and unlined manholes, and box culverts in sizes ranging from 750 by 750 up to 3,500 by 3,500 mm for storm water and sewage projects.

It produces telecommunication manholes, handholes, precast housing units and fence walls.

Sophisticated HawkeyePedershaab VIHY Multicast machines currently form the backbone of T Nagadi’s two plants, where a total of 18 drycast VIHY concrete vibration machines manufacture pipes and manholes as large as 3,600 mm in diameter, and eight large cage-making machines are in operation for the production of cages up to 5,500 mm.

- Flowcrete systems give floors long life

- Putzmeister unveils new-generation pump

- PI Makina mobile plant goes extra mile

- Concremote offers ‘know-when’ on site

- T Nagadi boosts production capacity