Right plaster beads key to aesthetic structures

01 November 2014

RICHARD PRICE, technical director of Catnic, looks at some key considerations when selecting plaster beads and provides a step-by-step guide for specifiers in the Middle East.

The Gulf region has a great selection of architectural masterpieces and is well known for wonderful creations made from steel and glass to concrete and render.

The selection of quality products is vital in reflecting the design aspirations held by the architects and achieving the desired building finish. However, the impact of poorly specified building components can be very detrimental to the overall visual effect, structural integrity and performance of a building.

The Middle East region has recently taken the lead in meeting sustainability standards with the realisation that buildings are responsible for at least 40 per cent of energy use in the UAE1, for example. The Middle East Centre for Sustainable Development (MEDCSD) encourages energy to be valued, trying to educate and motivate those involved in building to focus on improved energy efficiency. About 73 per cent of architects, engineers and construction professionals have a new green project planned in the UAE2.

To ensure that a building has its environmental credentials, the first step is to manage the external envelope, which requires careful planning as the building is made up of multiple materials. But for a top quality finish to these buildings, it is also paramount that the correct building components are specified.

For an internal or external wall finish to be successful, both in its installation and in its operable lifetime, it must be robust. This entails withstanding the effects of climatic conditions – much of the region faces excessive heat and often very moist and saline-heavy air. It also entails standing up to the rigours of daily use, including the knocks and scrapes all buildings must endure.

|

|

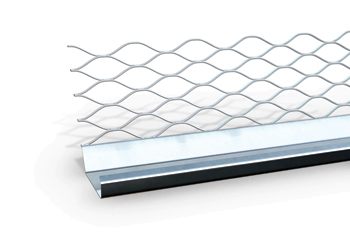

Galvanised architrave bead. |

When considering the wall finish, wet plaster or drywall internally and render finish externally, it is important to get the specification of the plasterers’ beads right in order to ensure a long-lasting result. Plasterers’ beads will help give a neat, crisp and professional finish while helping to avoid cracking and splitting, which can inevitably cause issues with the paintwork or wallcoverings. Seeking advice from a consultant or specialist who understands how beads of differing materials will perform in individual circumstances is the key to getting this right but essentially, there are five main points for specifiers to consider when choosing plaster beads:

• The first consideration is to select beads which are of high quality. Quality provides rigidness and strength, which helps to make sure that the bead is straight and remains straight throughout installation. This will give a precision finish as well as being quicker and easier to install, resulting in reduced labour costs. Quality will also help in applying the correct level of plaster, which will stop the bead showing through. A strong indicator of quality is a bead that is manufactured from a thicker gauge steel, such as the ones offered by the UK-based Catnic, which are manufactured from 0.44-mm steel.

• It is also key that all punching and forming is of a consistently high standard and for this, beads, such as the Catnic range, which comply with the European standards – BS EN 13658-1:2005 and BS EN 14353:2007 – are the best choice.

• It is now important to select the most appropriate bead for the job in hand. Internally, galvanised steel beads should be used whereas externally, stainless steel and PVCu (unplasticised polyvinyl chloride) should be used. It is important to note that both stainless steel and PVCu beads can be used internally in areas where there is high moisture or damp. PVCu, in particular, should be used in very aggressive climatic conditions.

• It is also important to consider that there are also specific beads for dry-lining applications as well as beads specifically for wet plaster and external render applications. This needs to be taken into account during selection.

• The design of the beads should also be considered – there are a number of designs for different uses such as angle, plasterstop and architrave beads.

Getting the specification of building components correct is more crucial than ever as specifiers in the Middle East are looking to achieve the desired performance and finish of buildings to help maintain reliable construction methods, and to keep costs down. Catnic, a Tata Steel enterprise, has a reputation for superior quality and reliability, backed by excellent service and technical support with a record for introducing new and improved products, helping the building industry in the region meet the ever-changing demands of the environmental and economic market.

Catnic is exhibiting at The Big 5 show to be held at Dubai World Trade Centre in Dubai, UAE, this month (November 17 to 20). It can be visited at Stand 2E61, Hall 2.

References:

1. http://www.mecsd.com/green_building/

2. http://greengopost.com/middle-east-shift-towards-sustainability-a-boom-for-green-building-suppliers/

- Rooms bonanza for the region

- Meva systems speed up work on Dubai tower

- Sahyadri’s Ecopro offers the green option

- Spectra ready to take on security challenges

- UBM expands range of door hardware

- FnD set to complete flooring for restaurants

- Right plaster beads key to aesthetic structures

- Masa offers wide range of pesticides