Lindapter type AAF clamp features tight grip

01 November 2014

Lindapter, the inventor of the girder clamp and Hollo-Bolt, has developed a new steelwork clamp for connecting steel sections, offering adjustability, anti-corrosion protection and high load capacities, even in low temperature environments.

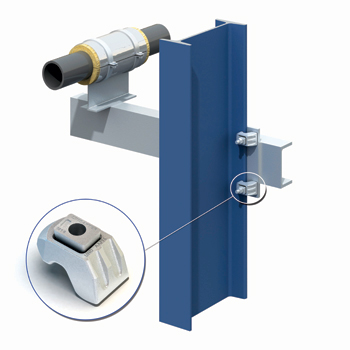

“The Type AAF, Lindapter’s flagship product, is the latest addition to its high slip resistance (HSR) family of clamps designed for high load requirements including frictional, tensile and combined load applications,” says a spokesman for the UK-based pioneer in steelwork connections.

The clamp features an innovative two-part design that self-adjusts to suit a range of flange thicknesses, allowing contractors to use a single product type for multiple connection requirements. Typical applications include securing steel-framed roofs, heavy pipe supports, mechanical handling equipment and bridge strengthening apparatus.

Manufactured from SG iron to EN 1563 with specific low temperature properties, the Type AAF provides resistance in cold environments where impact strength is important. Durability also extends to corrosion protection as the product is supplied with a hot dip galvanised coating as standard.

“Engineers can be confident that they are specifying a safe and reliable connection as load capacities have been independently verified by TÜV Nord,” the spokesman says. “Compared to conventional methods such as drilling or welding, the Type AAF can be installed in minutes without the need for hot work permits, reducing construction time and labour costs.

For additional convenience during installation, Direct Tension Indicators (DTIs) can be used to ensure the correct tension is applied to the fasteners. The Type AAF is available in sizes M12 and M16.

- Case raises bar with new loaders

- Knauf makes monolithic ceiling surfaces possible

- Lindapter type AAF clamp features tight grip