Greenheck launches grease trapper

01 February 2016

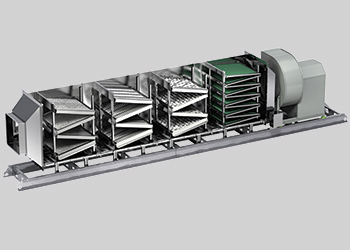

Greenheck says its new Grease Trapper Pollution Control Unit removes grease, smoke and odours from kitchen exhaust and has been tested and listed to the UL-1978 standard for factory-built grease ducts.

The grease trapper uses a three-stage mechanical filter arrangement to remove grease and smoke particles from the exhaust air at an economical first cost, says a spokesman for the US-based company.

“For ease of maintenance, independent pressure switches signal when any of the three filter stages need replacing,” he adds.

Activated carbon panels remove odour molecules prior to discharging the air, reducing the impact of kitchen exhaust to the surrounding areas. Built in accordance with NFPA 96, the grease trapper has performance capacities up to 12,000 cfm and MERV (minimum efficiency reporting value) filters ensure a minimum overall particulate removal efficiency of 95 per cent.

Greenheck is the worldwide leader in manufacturing and distributing air movement, conditioning and control equipment. This includes fans, dampers, louvres, kitchen ventilation hoods, and energy recovery and make-up air units.

Its flagship ventilation products are typically found behind walls, in ductwork or on the roofs of hospitals, office buildings, hotels, shopping malls, restaurants, schools, industrial plants and other commercial buildings. Their function, basically, is to move air in, out and around a building — making life inside a lot more pleasant.

Greenheck equipment is used in all types of commercial, institutional, and industrial buildings in applications ranging from comfort ventilation to manufacturing processes.

Greenheck is also a major, multi-brand corporation, representing a number of other affiliated entities (Accurex, Airolite, Innovent, Precision Coils, and Valent) offering architectural louvres and sunshades, specialised air-handling systems, heating and cooling coils and many related accessories and services.