Daimler launches a transport revolution

01 May 2016

Daimler Trucks has staged the global premier of its ‘Highway Pilot Connect’ system, demonstrating its technological leadership in the field of connectivity and consolidating its worldwide leadership in connected trucks.

In late March 2016, on the A52 autobahn near Dusseldorf, Germany, Daimler Trucks presented an impressive example of the possibilities opened up by the digital connection of trucks: Three wifi-connected, autonomously driven Mercedes-Benz trucks operated on the autobahn with authorisation for public traffic as a so-called platoon. Based on the Daimler Trucks Highway Pilot system for autonomously driving heavy trucks, the three trucks linked up to form an aerodynamically optimised, fully automated platoon. Daimler Trucks calls this advanced system development Highway Pilot Connect.

“The completely connected truck initiates a radical change in transport which will make traffic even more effective and efficient – not only for drivers, haulers and vehicle manufacturers, but also for society as a whole,” says a spokesman for Daimler. “The combination can reduce fuel consumption by up to seven per cent and the road space requirement on motorways by almost half – while improving traffic safety at the same time.”

Dr Wolfgang Bernhard, member of the board of management of Daimler with responsibility for Daimler Trucks and Buses, elaborates: “We are connecting the truck with the internet – making it the main data node of the logistics network. It connects all those involved in goods: drivers, schedulers, fleet operators, workshops, manufacturers and insurance companies or authorities. They receive information in real time, which was previously unavailable: about the condition of the tractor unit and semitrailer, traffic and weather conditions, the parking availability at motorway service stations, rest areas and much more

|

|

The function on the dashboard. |

“In the future it will, for example, be possible to reduce waiting times while loading and unloading, reduce paperwork and avoid traffic jams. With flash updates over the air or automated transfer of inbound time for trucks heading to the service point, maintenance time can be reduced significantly. In this way, we are considerably improving the performance of goods transport as a whole. This is an enormous opportunity to intelligently cope with the growing volume of goods traffic. We intend to use it.”

Daimler’s smart trucks have the potential to radically change road goods transport in the coming years. Today, Daimler Trucks generates valuable information to a previously unimaginable extent with its approximately 400 sensors per vehicle and is fully connected with software including 130 millions of lines of code – more than a passenger jet.

Dr Bernhard has further announced an investment of €500 million ($568 million) by 2020 to connect Daimler trucks with their environment and develop specific new applications.

“FleetBoard and Detroit Connect will help considerably to leverage previously unharvested potential in road transport – both in the highly developed triad markets and in the emerging economies of Africa, Asia and Latin America,” he adds.

FleetBoard, a subsidiary of Daimler Trucks, has been a leader in telematics services for trucks for 15 years. It will be the nucleus of Mercedes-Benz’s new unit, Digital Solutions and Services, which will direct all activities concerning digital applications for Mercedes-Benz commercial vehicles – in close cooperation with the other divisions of the company. At present, there are around 180,000 vehicles with FleetBoard systems in operation with around 6,000 customers.

|

|

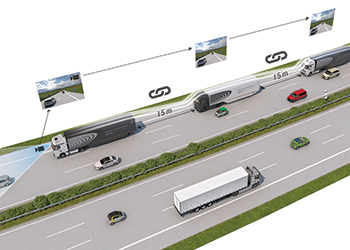

Platooning also allows much more efficient use of road space: |

Bernhard explains that connected vehicles in a platoon require a distance of only 15 instead of 50 m between them. This considerably smaller distance produces a significant reduction in aerodynamic drag, and the platoon can achieve a fuel saving of around seven per cent, reducing carbon dioxide emissions in the same measure.

Platooning also allows much more efficient use of the road space: a platoon of three linked trucks has a length of only 80 m (trucks not electronically docked require a total of 150 m). At the same time, platooning makes road traffic much safer, reducing reaction time to less than 0.1 seconds with Highway Pilot Connect compared to a human reaction time of 1.4 seconds.

“A great advantage of Highway Pilot Connect is this: because of their technology, all the members of such a platoon continue to be autonomously driving trucks,” says the spokesman. “They are able to maintain their direction independently of the vehicle ahead, and thanks to their combination of linear and lateral guidance, they can react to unexpected situations at any time. This also applies if other vehicles cut into or leave the platoon’s space. In this case, the vehicle can smoothly disengage from the platoon and continue alone in autonomous mode. The driver does not need to intervene.”

Experts expect the worldwide volume of goods carried by road to triple by 2050. By networking trucks, the entire goods transport sector can be organised to be safer, faster and at the same time more environment-friendly, says Bernhard.

The Daimler Group is one of the largest producers of premium cars and the world’s biggest manufacturer of commercial vehicles. Its divisions include Mercedes-Benz Cars, Daimler Trucks, Mercedes-Benz Vans, Daimler Buses and Daimler Financial Services. In 2015, the group sold 2.9 million vehicles and earned a revenue of €149.5 billion ($170 billion).

- Daimler launches a transport revolution

- MasterLine 8 stands for comfort, security

- New Peri system uses fibre-reinforced plastics