Chillers made for Mideast

01 July 2017

Daikin’s EWAD-MZ chillers have been customised for the region and offer high efficiency even at soaring temperatures.

Daikin has launched its next generation of air-cooled chillers, which have been customised for the Middle East to ensure the highest overall efficiency particularly in the region’s high ambient temperatures.

These units have been designed to bring down energy costs and the carbon footprint, making them the first choice for designers, consultants and end-users over traditional air-cooled chillers, says the manufacturer.

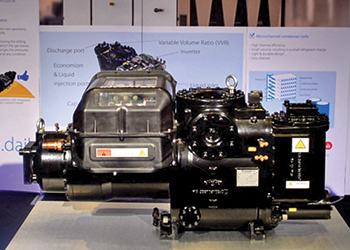

The premium efficiency EWAD-MZ series chillers use Daikin’s proven screw compressors, incorporated with industry-first variable volume ratio (VVR) technology that allows the internal compression ratio to optimise the chiller’s performance at all ambient conditions, it adds.

“Thanks to this innovative solution, Daikin VVR can avoid those energy losses typical of traditional compressors designed with fixed volume ratio. No more over-compression phenomena are experienced with Daikin VVR,” says Marco Flavio Calanca, marketing manager at Daikin Applied Europe.

VVR combined with an inverter on compressors (each compressor has its own dedicated refrigerant cooled inverter) provide best-in-class efficiency at every load and lift condition, he adds.

“Thanks to the refrigerant cooling system, the inverter temperature is precisely controlled and maintained at optimal conditions, regardless of the outdoor temperature and air quality. Daikin refrigerant cooled inverter is specifically designed for trouble-free operation even under extreme conditions such as high ambient temperatures and desert installations,” says Luca Del Ferraro, engineering department manager at Daikin Applied Europe.

EWAD-MZ demonstrates Daikin’s philosophy of customising global products to meet local needs and regulations, ensuring the highest overall efficiency and reliability for year-round operation in the Middle East.

Besides the refrigerant-cooled inverter, EWAD-MZ is provided with high-performance fans with enhanced air flow across condenser coils, allowing the unit to operate in up to a 55 deg C air ambient temperature without unloading. Various options of factory-applied condenser coil coatings are also provided to suit the region’s coastal environment.

Highlighting the advantage of the innovative ‘VVR + Inverter’ technology, Paras Adhvaryu, regional business director – chillers and modular plants, says: “Combining VVR + Inverter technology, EWAD-MZ provides the region’s consulting engineers and end-users with the right balance between the design of air-cooled chillers which can operate at the peak ambient conditions of the Middle East (typically 46 deg C), and the advantage of lower operating cost at lower ambient/reduced load conditions (prevalent during more than 90 per cent of the annual operating hours).

This is significant especially with the ever-increasing energy costs and the reduced energy subsidy in the region.”

The new EWAD-MZ series is manufactured at Daikin’s global manufacturing facility in Cecchina-Rome, Italy. Its performance is AHRI (Air Conditioning, Heating and Refrigeration Institute) certified with an IPLV (integrated part load value) as high as 6.6 and it is available in three efficiency versions (silver, gold and platinum), allowing a choice to meet project-specific requirements.

Commenting on the launch of the EWAD-MZ Series chillers, UAE sales director Samer Alawiah says: “In line with the UAE government’s evolving directives and strategies on sustainability as a core theme for future developments, Daikin is committed to developing and introducing state-of-the-art products and solutions, specifically designed for the region, achieving the highest efficiency, performance, and reliability.”

“Daikin Chiller and Air Side product ranges are now extended to meet all type of applications and requirements. To put it simply, Daikin has set a new standard in the HVAC industry,” he concludes.

- Chillers made for Mideast

- Greenheck unveils latest lines

- Fans take design cues from whale

- Intelligent way to fresh air

- York VRF system in the spotlight