T Nagadi expands as demand rises

With over two dozen plants, the Saudi producer of concrete products is well placed to meet the needs of major sewerage projects in the region.

01 March 2018

T Nagadi Preformed Concrete Factory is on an expansion drive, installing new machinery and opening additional facilities to meet the growing demand for its products in major infrastructure projects in the region.

The 100-per-cent Saudi company is one of the largest producers in the Middle East of concrete products, namely sewer and stormwater drainage pipes, manholes and box culverts and other concrete products.

The company’s products include concrete pipes in dimensions of 300 to 3,600 mm (with and without lining for open trenches and micro-tunnelling), lined and unlined manholes, and box culverts (from 750 by 750 mm to 3,500 by 3,500 mm) for stormwater and sewage projects.

It also produces telecommunications and electrical manholes and handholes, precast housing units and fence walls.

“In line with our vision, there is no compromise on quality and we strictly adhere to international standards. And that is the reason we are the market leaders for concrete products,” Saif Nagadi, the company’s vice-president, tells Gulf Construction.

|

|

Box culverts ... T Nagadi can produce various dimensions. |

He says T Nagadi is planning to increase production output while maintaining international quality standards. “New types of machinery are being added to manufacture concrete products as well as other products related to the construction industry, as per the market demand so as to support the infrastructural growth of the region,” he adds.

In fact, Nagadi says the T Nagadi factory has virtually no limitations in producing any concrete product that is demanded by the market, without compromising on quality.

T Nagadi currently has more than two dozen automated production plants in various locations. It has factories in Al Kharj (Riyadh), Yanbu and Tabuk, and sales offices in Riyadh and Jeddah.

The company recently relocated its Riyadh factory to a much larger premises spread over 150,000 sq m of industrial land procured in Rafaya Industrial Estate near the Al Kharj Road. This facility became operational three months ago.

Commenting on the new location, Nagadi says: “The land area where the company was located within the Riyadh city limit had become too small for further expansion or adding further machinery and products storage. To overcome these space limitations, and keeping in mind the future requirements of the Saudi market, we procured new land near the Al Kharj Road.”

Meanwhile, in Yanbu, with its latest machinery installation, T Nagadi is now able to supply box culverts in multiple modular patterns in dimensions of up to 3,500 by 3,500 mm. In addition, it can provide pipes for jacking and products with internal linings made of both high-density polyethylene (HDPE) and glass-reinforced plastic (GRP) required by some of the largest infrastructure projects in Saudi Arabia and neighbouring countries such as Iraq, Qatar, and Oman, he says.

Yet another production facility in Tabuk is set to commence operations shortly.

|

Concrete pipes in dimensions of 300 to 3,600 mm are part of T Nagadi’s wide products range. |

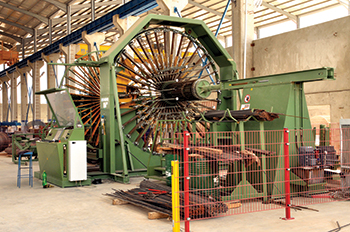

T Nagadi also has eight large cage-making machines in operation for the production of cages of up to 3,500 mm in diameter for pipes as well as for box culverts.

T Nagadi’s factories in Riyadh and Yanbu have witnessed rapid growth, with the Riyadh facility in particular having evolved from being a relatively small precast concrete plant into becoming one of the largest Middle East manufacturers of concrete pipes, manholes and box culverts for stormwater and sewage projects, covering all of Saudi Arabia.

According to Nagadi, although T Nagadi started its dry cast concrete vibration activities in Riyadh – where the demand for concrete pipes and manhole products has always been high – it has from the outset been focusing on new developments that have been anticipated for the Western region. “The lack of infrastructure in the regions around Jeddah and the new planned cities around Rabigh were obvious target markets,” he adds.

“With our latest installation in the Yanbu plant and with easy access for land transportation, this was considered to be an ideal location to serve the Western region with such infrastructure products,” says Nagadi.

The company was established in 1977 by Tarik Mohamed Ibrahim Nagadi who intended to set up a combination of automated and semi-automated units of versatile vertical and core vibration machines capable of manufacturing large varieties of pipes and manholes. The firm has recently added box culverts to its capability and has the capability of interchanging moulds for machines installed in Riyadh and Yanbu.

Hawkeye Pedershaab VIHY Multicast programmed machines have been the backbone of the company’s plants in Riyadh and Yanbu, where a total of 18 dry cast VIHY concrete vibration machines with capabilities to manufacture pipes and manholes as large as DN 3,600 mm in diameter are in operation, Nagadi says.

In addition to its existing machinery, the company plans to procure further sophisticated machinery with high output capacity to meet the demands of infrastructure developments in and around Saudi Arabia and the GCC countries, he concludes.

- T Nagadi expands as demand rises

- Viega makes joining easier

- Polypipe specified for key projects

- Masa pulls the plug on roaches