Lisec’s latest in the spotlight

01 October 2018

At Glasstec 2018 this month, Lisec has lined up an innovative products showcase that focuses on the areas of glass cutting, glass processing, flat glass lamination, and insulating glass production.

Glasstec, a leading trade show for glass production, processing and products, will be held from October 23 to 26 in Dusseldorf, Germany, where the Austrian solution provider’s 2,300-sq-m exhibition booth is themed “we innovate for your success”.

Among its latest innovations that will be promoted are SprintCut, a high-performance machine for cutting flat glass. Claimed to be the fastest on the market thanks to state-of-the-art linear drive technology, it has a maximum acceleration of approximately 16 m/sq second and a maximum speed of 310 m/minute. The quiet SprintCut offers outstanding flexibility, has low mechanical wear, requires less service intervals and results in low downtime costs, says the company.

|

|

The LBH-B25ARS ... an automatic butyl extruder for solid spacers. |

Other products in the spotlight include:

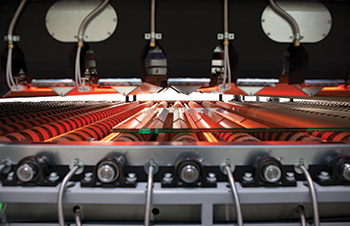

• VSL-A37/33: This high-performance machine for automatically cutting laminated glass promises a 30 per cent increase in output thanks to innovative separating bar technology. Its automatic raw glass measurement technology makes it more precise (+/- 3 mm) than comparable solutions. The VSL-A37/33 has a 50 per cent higher cutting speed, and the glass rotating and positioning is done automatically. It cuts top-quality edges because of the dual cutting head – two each on top and on the bottom – and Power-IR foil heating. There is low wastage thanks to trim cutting of 20 mm on all four sides.

• SplitFin: This machine line is used to process flat glass using water jet technology. It is a new vertical processing concept that is simultaneously modular and fully integrated. SplitFin uses the special advantages and highlights of individual machines. In contrast to the all-in-one centres or stand-alone solutions, this processing line can be used for high output of the complete line, but at the same time, the individual machines may also be used, depending on the requirements.

The individual devices and systems that make up the SplitFin’s core components include: The EPS vertical fully automatic edge grinding machine, with one or two grinding heads and automatic tool changing; the MRX-B drilling and milling centre with integrated tool changing and patented Lisec water jet technology; and the topClear glass washing machine.

• ConvectLam2: This laminating machine for flat glass features a high-pressure autoclave. The machine provides energy savings, thanks to its intelligent radiator heater box convection system; highly homogeneous glass heating because of its special air convection system; exact pressing force/pressing path adjustment via servo motor-controlled presses; and high positioning accuracy. If additional equipment like the autoclave and cleanroom are selected, it enables turnkey production of laminated glass and laminated safety glass.

• LBH-B25ARS: This is an automatic butyl extruder for solid spacers used in the production of insulating glass. It can process spacer frames up to a maximum size of 2,500 by 2,500 mm, and offers precise, interruption-free application of butyl ranging from 1.5 to 4.5 g/m.

• BSV-B45NK: This is a patent-pending bending machine for ‘sharp’ corners used in the production of insulating glass. Its spacer bending features a sharp 90-degree transition and is especially suitable for hybrid and plastic spacers.

Headquartered in Amstetten, Austria, Lisec has been offering solutions in the field of flat glass processing and finishing for over 50 years. Its service portfolio includes machines, automation solutions and services.

Lisec develops and fabricates glass cutting and sorting systems, single components and complete production lines for insulating glass and laminated glass fabrication as well as glass edge processing machines and tempering machinery.

- Hi-Finity doors high on aesthetics, performance

- Security panels show might in the line of fire

- Lisec’s latest in the spotlight