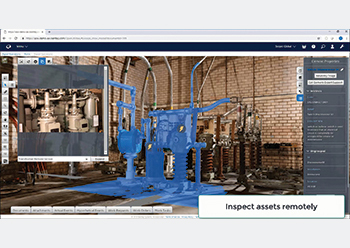

Digital twins can merge information from a variety of sources for immersive visualisation and analytics visibility.

Eyeing a connected data environment

BRIAN ROBINS of Bentley Systems* highlights the need to integrate digital information through an open connected data environment, so that engineering, information, and operational technologies can be brought together to improve the throughput, safety, and reliability of infrastructure assets.

01 July 2019

For the last decade, we have been asking: how can the engineering and construction industry be more like manufacturing? How can we industrialise project delivery and construction workflows and turn what is a bespoke industry into an automated, repeatable, predictable industry? How can we apply industrial concepts such as the assembly line, standardised components, and repeatable processes to construction?

When they hear “industrialisation”, many people think about modularisation, offsite prefabrication, and on-site assembly. For them, industrialisation is shorthand for logistics. They might point to examples like the ones in China where contractors build complete skyscrapers in two weeks.

On the other hand, some will argue, industrialisation cannot alter the fact that every project is unique. The supply chain is unique, as are the site conditions, the season and the weather, and methods of delivery. The way we bid and the strategic decisions we take are also unique and so, to that extent, the competitive advantage lies in how the project is delivered.

|

|

Brian Robins, vice-president, product and industry marketing, Bentley Systems |

However, manufacturing is undergoing its own transformation to dematerialisation or “servitisation”, sometimes encapsulated as the fourth industrial revolution or “Industry 4.0”.

Instead of asking how construction can be more like manufacturing, perhaps the better question to ask is: how can engineering and construction be more like an information business?

Our industry has moved from document-centric to model-centric, and we are now entering the era of the digital built environment, which is unquestionably data-centric.

Having accurate, trustworthy, and actionable data is not merely a competitive advantage but might also be an existential issue. Like it or not, we are in the business of asset outcomes, and digital assets

are as important as the physical assets they represent.

Data is the new infrastructure and whoever has the most data usually wins.

Digitisation or digital transformation?

What is preventing widescale adoption of digital technologies? How can engineering and construction firms be data-driven, digital businesses? The low hanging fruit for many firms has been the introduction of smart phones and tablets in the field and collaboration based on PDF mark-up. We have digitised our documents and deliverables in the form of PDFs, but our workflows and processes are still essentially analog. PDF is in a sense a “permanently dark format”.

Other firms point to building information modelling (BIM) models as evidence of digital transformation. But we need to agree whether a digital engineering model is a legal contract or simply supplemental information. Who owns it? Who has liability for it and who is responsible for maintaining it?

Often, the contractor discards the design BIM deliverables and starts over. Then, is the contractor’s BIM model an inspection report of tolerances or is it an as-built?

Contractors may be able to hand over some form of data but what many owners struggle with is having no place to put it or maintain it.

When there is a requirement for records retention of up to 40 years, information including BIM models and datasets needs to be accessible, shareable, and maintainable. Practical experience proves that it is very challenging moving models from construction to asset management, not least for the simple reason that operations and maintenance departments have very different IT systems from CAD or BIM.

Open, connected

So, where are digital technologies delivering value? Who is leading the charge and how are they able to drive success?

The next step for many organisations is to implement a connected data environment to have open and live access to information within digital engineering models, so that engineering technologies (ET) can be brought together with information technologies (IT) and operational technologies (OT) to improve the throughput, safety, and reliability of infrastructure assets.

An open CDE ensures that BIM deliverables are of use to owners. BIM deliverables can be updated as-constructed to enable operations and maintenance to capture the asset performance opportunity.

An open connected data environment is an opportunity for digital engineering models to be more useful, to serve as a baseline and framework for operational decisions, and derive actionable insights.

An open CDE is used to collect, manage and share information about an asset. It facilitates collaboration between project team members and owner-operators, helping them avoid duplication and mistakes by incorporating multiple sources of data into a digital twin model.

An open connected data environment, provisioned by or for the owner as a cloud service, captures and intelligently shares all digital work packages, enabling participants to automate their collaboration protocols as if they were one project enterprise.

Through an open CDE, organisations can control the status and quality of asset information as it evolves, no matter the source, and support business processes that require multiple data sources across all lifecycle phases.

Engineering information produced during the project delivery phase of the asset lifecycle can be used to derive timely and actionable insights, supporting operational decisions that improve asset performance.

Digital integrator

The engineering and construction industry needs to deploy the latest technologies that can help achieve value. What can you do to accelerate your digital advancement? How can your firm become a digital integrator?

Infrastructure asset owner-operators have recognised the potential for leveraging digital twin models in many use cases, including the application of analytics, artificial intelligence (AI) and machine learning (ML) in simulations and decision support throughout the lifecycle of design, construction, and operations.

The most significant and overarching digital opportunity is to leverage digital twin models created within project delivery to become the performance digital twin, or “digital DNA”, for infrastructure asset performance during operations and maintenance.

There are huge opportunities for firms to create and curate digital twin models, to take legal responsibility for data, and to use verifiable, timely, and accessible data to enable better informed decisions.

By implementing an open, connected data environment and digital workflows, engineering and construction can operate more like an information business and deliver better asset outcomes.

* Brian Robins is vice-president, product and industry marketing at Bentley Systems*, a software development company that supports the professional needs of those responsible for creating and managing the world’s infrastructure, including roadways, bridges, airports, skyscrapers, industrial and power plants as well as utility networks. Bentley delivers solutions for the entire lifecycle of the infrastructure asset, tailored to the needs of the various professions. Comprised of integrated applications and services built on an open platform, each solution is designed to ensure that information flows between workflow processes and project team members to enable interoperability and collaboration.