Terex MPS expands crusher choice

01 June 2020

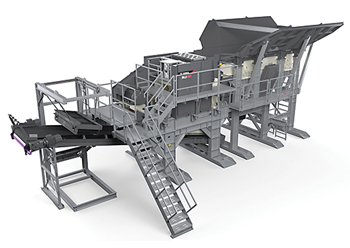

Terex Mineral Processing Systems (MPS) has launched the new Terex MPS MJ55 modular jaw crusher which has been designed for large quarries or contractors that want a stationary-type unit without the complexity of a normal stick-built plant.

Based on the company’s proven, high-performance JW55 jaw crusher, the module combines the JW55 jaw crusher, a sloped hopper, 52-inch by 20-ft feeder, and straight line conveyor on a galvanised/painted steel structure. This structure can be transported in standard shipping containers plus a flat rack for the crusher and can be bolted together quickly on site with basic tools, says a spokesman for the company which offers a comprehensive crushing and screening product line.

The three configurations offered for the feed hopper allow for the optimum size to match up to the equipment that is being used to load the machine, he adds.

The structure includes oversize walkways, repositionable stairs and guard rails for safe access. Three plant emergency stops are placed conveniently around the platform for easy access during operation. In addition, optional mounting feet allow for the basic unit to be installed on compacted gravel base.

The MJ55 comes with hydraulic CCS jaw adjustment controls. Additional options include a cross plant magnet, switchgear panel and off plant conveyor starter kit.

Meanwhile, following the recent launch of the Terex MPS TG/TGS Series bushing cone crushers, the company has now introduced the MC320 cone module. The cone module features the TG320 or optional TGS320 cone on the same universal base structure as the MC and MV Series modular lines. The all-electric, pre-engineered solution can be easily transported in standard containers and can be bolted together onsite quickly with basic tools and minimal wiring and installed with or without full concrete foundations.

|

|

The MC320 cone module ... easily transported. |

“The TG320 is a 300 hp bushing cone with large feed opening, adjustable eccentric throw and multiple liners that allow the operator to quickly and easily optimise production output in almost any application. The 300 hp (225 kW) 1,800/1,500 rpm motor and crusher are mounted on a rubber isolated frame, common between modular, portable and static platforms,” the spokesman explains.

As with the MJ55, the galvanised/painted steel structure includes oversize walkways, repositionable stairs and guard rails for safe access. Four plant emergency stops are placed conveniently around the platform for easy access during operation.

The MC320 comes with standard AIC crusher controls. Additional options include an overflow chute and off plant conveyor starter kit.

A Terex MPS unit was recently commissioned in Ras Al Khaimah to support the production of steel-grade limestone for JSW Cement, a wholly-owned subsidiary of India-based JSW Cement. The Terex 1200TPH plant consists of a primary jaw crusher – the Cedarapids JC5460 (the biggest jaw crusher offered by Terex); a secondary cone crusher – Cedarapids MVP 550 X; a tertiary vertical shaft impactor – Canica 2000, with multiple screens in the process including the MTS 6204, Cedarapids TSV8203, a dual mechanism screen from the US and torrent offerings from Malaysia.

The impressive set-up spans about 420,000 sq m and produces 20,000 tonnes per day ranging from 0-5 mm, 5-10 mm, 10-20 mm, 20-40 mm, and 40-80 mm.

Terex Corporation is a global manufacturer of lifting and material processing products and services delivering lifecycle solutions that maximize customer return on investment. Major Terex brands include Terex, Genie and Powerscreen. Terex solutions serve a broad range of industries, including construction, infrastructure, manufacturing, shipping, transportation, refining, energy, utilities, quarrying and mining.

- Metso boosts crusher range to meet demand

- Cat achieves milestone in autonomous haulage

- CDE sand washing tech boosts concrete quality

- Bison geared to tackle hard rock

- Terex MPS expands crusher choice