Vinneva, a booster for bitumen coatings

Vinneva polymers enhance bitumen-based building coatings, boosting their adherence properties. Furthermore, Vinneva-modified bitumen also provide protection from water ingress, says RAJENDRA KHOLIYA, Business Development Manager, Wacker Chemicals Middle East.

01 September 2020

Germany-based chemical company Wacker’s recently-launched polymer Vinneva for bitumen emulsions ensure that the coatings adhere exceptionally well to the building fabric for a long time. In addition, they can also reinforce the barrier effect against water pressing in on a basement wall or other building parts.

Bitumen finds use in a various applications such as road construction and water-repellent coatings. In the Middle East and Africa (MEA), these coatings are usually polymer-modified, that is, they contain polymers that enhance the property profile.

Wacker has developed binders based on vinyl acetate-ethylene (VAE) copolymers specifically for bitumen emulsions under the tradename Vinneva. The product line is intended to convince users of non-modified bitumen emulsions of the benefits of a polymer additive – making the coatings more flexible and more resistant to all kinds of mechanical stress. In addition, Vinneva offers several advantages over polymers that have been used in bitumen emulsions to date. These are mainly elastomers, that is, rubber-like substances, such as styrene-butadiene rubber (SBR) and polychloroprenes.

|

|

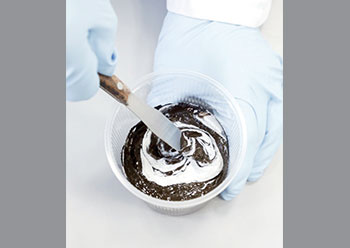

Vinneva added to a conventional bitumen emulsion enhances its properties. |

Excellent adhesion

A Vinneva content of several percent – depending on the formulation – increases the performance of bitumen tremendously. Vinneva-modified formulations outperform other modified bitumen emulsions, especially when it comes to tensile adhesion strength and elastic recovery. Extensive tests at Wacker’s laboratories have shown that the tensile adhesion strength increases by up to 60 per cent compared to conventional modified bitumen emulsions.

In order to test tensile adhesion strength, technicians first apply the bitumen emulsion to a concrete slab. Once it has dried, they cut circular test areas into the coated slab and stick a metal test piece onto each one of these areas. The technicians then measure the force required to pull the test pieces, including the bitumen coating sticking to them, from the concrete. The higher the necessary force, the more difficult it is to detach the coatings from the building fabric, hence, the stronger their adhesion to it.

Resistance to water pressure

A bitumen coating’s most important function is to protect basements, roofs or entire buildings from the ingress of water. In order to test how well a coating fulfils this function, technicians apply it to small concrete cubes and allow it to dry under specified climatic conditions. In a special facility, they then expose the coated cubes to an adjustable water pressure for seven days, for instance. After this duration, they measure whether any of the originally used water has been “lost” due to ingress into the concrete cube. These kinds of tests have demonstrated that bitumen emulsions that have Vinneva added to them can withstand positive water pressure.

There are further properties that characterise Vinneva-modified bitumen emulsions. One sample formulation took 3.5 hours to dry, for example. When the Vinneva component was replaced with another polymer – with the formulation otherwise being the same – the drying process took 4.5 hours. The dried coatings based on the new polymer are also less sticky than various other systems. In many cases, shorter drying times represent increased productivity for end customers, which can make the bitumen emulsion less costly to apply.

Methods of polymer modification

It must always be taken into account that the properties of a bitumen emulsion do not just depend on the polymers used, but also on the bitumen composition and other additives. Bitumen is a mixture of heterocycles, polycyclic aromatic hydrocarbons, and branched hydrocarbons with varying degrees of saturation. Depending on where the crude oil is sourced, the proportion of these compounds in bitumen varies greatly.

Coatings are based on bitumen emulsions that can be produced in colloid mills from hot bitumen and water that contains additives. There are two ways of modifying bitumen coatings with a Vinneva polymer: the polymer is either added to the water jet before the emulsion forms or to the bitumen emulsion at the end. In the Middle East and Africa (MEA) region, the latter method is commonly used.

This is why, for its customers, Wacker individually tailors its Vinneva polymers to the bitumen composition and additives and experts at Wacker’s local technical centre in Dubai, UAE, provide support. It is thus possible to formulate coatings that are superior to products based on other polymers with regard to key properties such as elasticity, elongation at break and watertightness.

Vinneva polymers are not only based on petroleum, but also on natural gas. That’s why their price fluctuates less in the long term than that of other polymers used for bitumen modification. In addition, unlike some other additives, they do not contain chlorine.

Vinneva polymers can also enhance fibre-reinforced or filled bitumen coatings. In the MEA region, water-based bituminous coatings are used as a primer for waterproofing membranes as well as back coatings for facades.