AIC’s project team translated the accurate construction layout directly into the field with the Tekla software, which exports extensive 3D models straight into Trimble FieldLink.

Trimble helps shape iconic station

01 March 2022

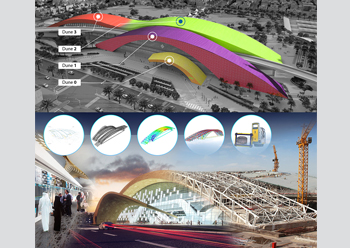

Trimble Solutions says its software was leveraged in the designing and detailing of the entire steel structures that make up the 3B2 Western Station, one of the iconic stations of the Riyadh Metro.

The station has been designed by Omrania & Associates as an intermodal transit hub southwest of downtown Riyadh. The 3B2 Western Station has a complex design inspired by the kingdom’s deserts, dunes, oases, and palm groves. Covering a gross area of 107,000 sq m, the four massive dune-like structures host an aboveground metro station, bus station, underground park-and-ride facility, and a mosque.

The construction of the Riyadh Metro itself – one of the largest infrastructure projects in the region – involved more than 56,000 on-site workers, engineers, and designers who ensured that this infrastructure reflected Saudi Arabia’s culture and heritage, according to Trimble Solutions.

“Given how massive and important this project was, our innovative solutions were leveraged, particularly in AIC Steel’s design of the 3B2 Western Station, which is one of the largest and most iconic stations. Our client, AIC, oversaw the design and details, including the entire steel structure of the station,” Paul Wallett, Regional Director, Trimble Solutions – Middle East and India, tells Gulf Construction.

|

|

Wallett ... focusing on providing local support. |

To achieve the desired level of details and specifications during the design and construction phases, AIC used Trimble’s hardware and software solutions.

“Trimble’s Tekla Structures, for one, had proved to be crucial with its powerful and intuitive 3D BIM capabilities, huge connection library, and absence of site fit-up issues. AIC’s project team translated the accurate construction layout directly into the field with the Tekla software, which exports extensive 3D models straight into Trimble FieldLink. AIC also incorporated the Trimble Robotic Total Stations to avoid any errors, thus delays in the work processes and to increase the efficiency of their job site layouts and measurements,” Wallett explains.

“These examples of innovative solutions are suitable for the construction sector as they enhance efficiency, simplify the work processes, reduce errors, and provide stability to projects,” he adds.

These software solutions afford a high level of flexibility and hence can be easily used on any project requiring minimum customisation, according to Wallett.

“Tekla’s powerful modelling tools were flexible to meet the complex requirements for the Riyadh Metro project. Since the project had irregular dimensions and shapes, AIC had to rely on Tekla Structures, a ready-to-use solution with minimum customisation required but with APIs (application programming interfaces) it can be further customised as per customer’s specific needs to streamline the workflows. The major challenges included building models from design drawings to show the nodes of the structure.”

Tekla Structures is an easy-to-use BIM solution for 3D modelling and detailing. If needed, Trimble can provide dedicated support teams to guide and assist its clients in implementing its solutions.

The Trimble Robotic Total Stations (Trimble RTS) allowed AIC to operate remotely, with one qualified operator to control the entire process while the rest of the team performed other crucial project tasks, Wallett explains.

“With this, they could create faster and more accurate layouts, improve handover, and enhance accuracy due to access to real-time data. The 3D models helped AIC with efficiency and precision far beyond the scope of a manual layout tool.

Tekla Structures helped AIC simplify the complex designs, facilitated and accelerated the modelling, drawings, and workflow needed for the metro station. Tekla solution enabled AIC to design complex trusses, secondary trusses, infills, and bracing that had to be arranged in a knotted configuration, in addition to purlins and facade support systems. In addition, Tekla Structures parametric macros, a powerful 3D BIM software, were used to connect multimember joints with different slopes and orientations.

“Manual processes and tools, changes in the project files, and a lack of direct communication can delay the project and increase data errors. These challenges were prevented by AIC’s use of Tekla and Trimble RTS during the design and construction of the 3B2 Western Station,” he points out.

Tekla Structures for BIM 3D modelling and detailing has also been used for the Riyadh botanic garden (King Abdullah International Gardens), among many other projects.

“It’s a complicated structure that was easily modelled, detailed and fabricated with Trimble Solutions,” Wallett remarks.

Apart from AIC Steel, Trimble solutions are being utilised by Zamil Steel, Saudi Binladin, Cleveland Bridge Steel, International Building Systems Factory, Al Shahin Metal, Arabian Consulting Engineering Centre, Al Rushaid and many more, according to him.

Wallett says Trimble has a local support person in Saudi Arabia backed by its support team in Dubai office. “They are always eager to help our customers in the Middle East region. We believe in providing local support to our customers which is easily accessible at any time,” he says.

“We understand that, in terms of technical expertise coupled with the rapid digital transformation in the sector, some clients need further support to fully optimise the features of our solutions in construction projects. Assisting and supporting our stakeholders are part of our commitment as a solution provider,” he adds.

Trimble has been present in Saudi Arabia for more than nine years, and also has projects in other parts of the region.

At the regional level, Trimble’s Tekla solution has also contributed to many significant projects such as the Burj Khalifa, Ain Dubai and the Museum of the Future in the UAE; King Abdullah Petroleum Studies and Research Center (Kapsarc), King Abdulaziz Centre for World Culture, in addition to Riyadh Metro in Saudi Arabia; and the Adly Mansour metro station in Egypt.

- Ambitious vision

- Mega deals expected

- Unique heritage hub

- Key deals for entertainment hub

- Trimble helps shape iconic station

- Work starts on $3.7bn Avenues – Riyadh

- Byrne builds on strength as single-source supplier

- Big 5 Saudi set to open doors in the capital

- Al Kifah KRB to launch green concrete