Ziehl-Abegg fans win FEI certification

01 July 2019

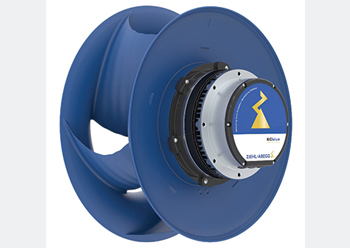

Ziehl-Abegg of Germany has become the first company worldwide to certify its product range – ZAbluefin – for the new fan energy index (FEI).

According to a company spokesman, FEI is an energy-efficiency metric for fans inclusive of motors and drives that provides a standardised and consistent basis for comparing fan energy performance across fan types and sizes at a given fan duty point. FEI also considers the effects of motors and drives, when included in fan-rating tests.

FEI was introduced in 2018 by the Air Movement and Control Association (AMCA) to save energy, reduce operating costs, and accelerate decarbonisation. The calculation method for the new metric is defined in ANSI/AMCA Standard 208 as the ‘Calculation of the Fan Energy Index’.

It is a replacement for fan efficiency grade (FEG), a metric currently referenced in model energy codes and standards such as ANSI/ASHRAE/IES 90.1, an energy standard for buildings except low-rise residential buildings; ANSI/ASHRAE/USGBC/IEC 189.1, a standard for the design of high-performance, green buildings except low-rise residential buildings; and the international energy conservation code and in federal regulations in several Asian countries.

The spokesman sees several uses for FEI. “Fan specifiers can use it to understand and communicate fan-efficiency design intent, while legislative and regulatory bodies can use it to define energy-efficiency requirements of fans. The standard has been written to support the fan industry’s entrance into energy and construction codes and standards and to support utility rebate programmes,” he elaborates.

A total of 27 of the company’s ZAbluefin centrifugal fans with GR modules in several combinations using different motors have been certified for FEI as are the former product range Cpro and C.

Ziehl-Abegg has been operating the world’s largest combined measurement and test chamber for fans in Künzelsau, Germany, since 2008. The company believes that state-of-the-art, high-precision measuring instruments and regular training for employees, combined with routine inspections by external organisations such as AMCA and TÜV, are essential to continuing to inspire customers’ total confidence in its products.

Located in Kuenzelsau, the family-owned Ziehl-Abegg is one of the leading international companies in the field of ventilation, control and drive technology. In the 1950s, it developed the basis for modern fan drives: external rotor motors, which are still seen as state-of-the-art worldwide.

Another area of Ziehl-Abegg’s business is electric motors which provide the power for elevators, CT imaging equipment and deep-sea underwater vehicles, among other applications.

With the introduction of the ZAwheel in 2012, the company established itself in the sector of electro-mobility as part of the Ziehl-Abegg Automotive Team.

Ziehl-Abegg employs 2,250 personnel in its production plants in southern Germany, and has a global workforce of 4,100 spanning 16 production plants, 29 subsidiaries and 111 sales locations.

Its products, approximately 30,000 in all, are sold in more than 100 countries. Its turnover in 2018 totalled €583 million ($663 million), with exports accounting for three quarters of the figure.

- Using architecture to create cooler homes

- Panasonic eco-friendly air-conditioners unveiled

- Galloway geared to boost indoor air quality

- Greenheck expands ventilation line

- Ziehl-Abegg fans win FEI certification