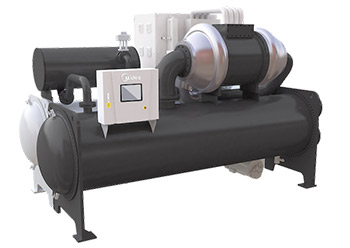

A standard CCWF model ... the one delivered to Tabreed site was slightly customised with the VFD panel being free standing instead of unit mounted.

Taqeef extends Tabreed’s AD16 chiller plant

01 April 2021

The final verified testing is currently being completed at Tabreed’s AD16 district cooling plant in Abu Dhabi, which is being expanded with the addition of a new 1,100-tonne high-efficiency chiller, according to Taqeef, a leading UAE cooling solutions provider, which was commissioned to expand the plant.

Taqeef says Tabreed accepted its proposal for a 1,100-TR factory-wired variable speed drive (VSD) water-cooled chiller with parallel operation from Midea in June 2020.

“As the largest district cooling provider in the emirate, Tabreed’s technical and commercial standards are second to none. It demands world-leading technology and world-leading service and uses stringent measurement and evaluation procedures in the selection of suppliers,” says Wael Deeb, Business Development Manager at Taqeef.

|

|

Deeb ... Taqeef conducted live virtual testing. |

This was the first time Tabreed had specified a Chinese manufactured chiller, he says, and by diversifying supply strategies into new markets Tabreed has been able to deliver cost and efficiency savings and gains in user comfort, he says.

Commenting on the technology, he says: “Midea’s chiller technology is the most patented and the most advanced in the market. Despite the company’s relative newness in the HVAC industry (it entered commercial air-conditioning – CAC – in 1999), it has already achieved No 1 status and through its aggressive investment into research and development (R&D) – four per cent annually, compared to the industry average of two per cent – it has achieved phenomenal growth. Its use of intelligent technology means Midea solutions have direct bottom-line impacts; cooling even bigger districts with smaller machines, smaller plant areas, smaller infrastructure costs and smaller environmental impact.”

Tabreed was looking for a supply partner who could meet its technology specifications and also its challenging overall plant room efficiency targets (averaging 0.84 kW/TR).

“Midea’s chiller solution had many designed-in efficiencies: high-efficiency copper tubes delivered a 30 per cent saving, while Full Falling Film (a patented technology) reduced refrigerant use by 40 per cent, enabling us to achieve a full-load efficiency of 0.646 kW/TR. Added to this were the benefits of the reduced heat transfer area (allowing for a more compact chiller) which secured additional infrastructure savings, equating to hundreds of thousands of dirhams,” he emphasises.

Engineering Edge

Supplying a project of this magnitude and strategic importance during the Covid travel restrictions was an added pressure, according to Deeb. Tabreed needed to witness all aspects of chiller testing to ensure stringent protocols were met.

“So, as a first in this project, we orchestrated a live virtual testing over two days – with cross-continent video call streams of a nine-point test schedule undertaken to successfully complete this process.

“To ensure complete integration with the existing Scada (supervisory control and data acquisition) system, and to facilitate the seamless transition to Auto mode, Taqeef also installed a 24/7 tech team for the two months before testing and commissioning – accompanied by a Midea factory engineer for the critical 10 days pre-commissioning stage. This gave the added security of hands-on supervision and consultancy to Tabreed’s O&M team and allowed pre-emptive action to anticipate any issues pre testing,” he adds.

According to Deeb, all design parameter setpoints and performance indicators on the plant have been achieved to date. Noise levels are lower than anticipated, and outputs achieving against targets, he adds.

He says, with Tabreed leading the way, Taqeef can demonstrate the clear advantages of looking beyond traditional cooling technologies to new emerging players in the HVAC market.

“Sustainability is here to stay, and the UAE’s Energy Strategy 2050 demands we increase the contribution of clean energy in the total energy mix from 25 per cent to 50 per cent while reducing our carbon footprint by 70 per cent. The wide adoption of energy-efficient chillers such as the technology used in the Tabreed AD16 plant is a clear indication of support for the UAE’s national agenda and for a future of greener, cleaner cooling,” Deeb concludes.

- In the front line in the Covid-19 fight

- RWI launches HVAC, MEP products unit

- Daikin aims to build on regional strength

- Dynair promises efficient, safe ventilation

- Closing the skills gap in the HVAC industry

- Taqeef extends Tabreed’s AD16 chiller plant

- Al Futtaim Engineering seals LG deal

- Empower’s DC building numbers up 6pc in 2020