Companies are being called upon to implement new industrial processes that respond to the new models of the circular economy, focusing on product recyclability.

First certified recycled aluminium window

01 May 2021

Tchnal, a leading architectural aluminium systems brand owned by the Norwegian multinational Hydro group, which is the world’s largest producer of aluminium, has launched what it describes as the first post-consumer certified recycled aluminium window in a bid to cater to the demand for greener buildings and conserve the world’s energy and raw material resources.

The new range of windows are produced using Hydro Circal 75R, a material obtained by crushing and remelting end-of-life windows or other objects with an equivalent alloy.

Hydro Circal 75R is claimed to be the world´s first certified recycled aluminium, where 75R means that at least 75 per cent of new aluminium comes from post-consumer material, explains Hesham Kameshki, Marketing and Business Development Manager at Hydro Building Systems Middle East.

“The result is an aluminium of the exact same quality as that of primary aluminium, but with far lower environmental impact. Using 75 per cent post-consumer recycled aluminium, certified by an independent external company, it produces 85 per cent less carbon dioxide (CO2) emissions and uses 95 per cent less energy in the melting phase.

|

|

Remelting post-consumer aluminium scrap for new uses is said to require only five per cent of the energy needed to produce the primary aluminium. |

“Using recycled aluminium in the production process means that a lower amount of heat (and therefore energy) is generated. This energy usually contributes to CO2 levels in the atmosphere, so by reducing the amount of energy required to create the material, we’re proactively doing our bit to reduce climate change. In short, Hydro Circal 75R is a far greater environment-friendly product than primary aluminium and contributes to the development of the circular economy,” he states.

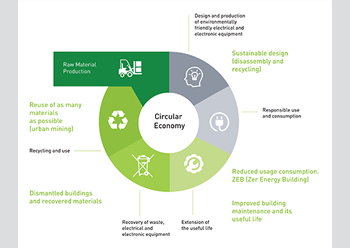

In today’s world of greater environmental awareness, the focus is on extending a product’s life cycle and implementing new industrial processes that recycle these products through reuse of as many materials, dismantling buildings and recovering materials and recycling and use.

“The life cycle of a product – from manufacturing to obsolescence – is increasingly becoming a priority factor when making consumption-related decisions. Companies are being called upon to implement new industrial processes that respond to the new models of the circular economy. Technal has demonstrated its commitment to sustainability by using Hydro Circal for its system solutions, one of the most sustainable aluminium alloys in our sector,” Kameshki remarks.

Unlike other materials, aluminium is infinitely recyclable and its quality and material properties are never lost, he points out, adding that estimates put the volume of aluminium objects in use worldwide at 200 million tonnes – all of which can be recycled at the end of their life cycle.

By recycling of post-consumer material, Hydro avoids the extraction of bauxite (the ore from which aluminium is obtained). The aim is to limit the exploitation of natural resources, even though aluminium is the third most abundant element on the planet. This apart, it extends the use of aluminium in these objects which would otherwise be discarded into landfills.

“This process, called urban mining, aims to turn cities into the main supply points of raw materials reducing the amount of waste and while keeping the natural resources intact. It reduces damage at the extraction site, the depletion of non‐renewable raw materials, sludge resulting from the manufacturing process, consumption of non-renewable energy and greenhouse gas emissions,” he emphasizes.

When seeking greener aluminium, it is important to note that Hydro Circal 75R comprises post-consumer recycled aluminium scrap – that is, aluminium that has been used before – rather than pre-consumer aluminium, Kameshki adds.

“The reduction in emissions compared to the worldwide average for primary aluminium production (18 kg of CO2 per kg of material) is drastic: with 2.33 kg of CO2 per kg of material, Hydro Circal is currently the aluminium with the lowest emission on the market and the objective is to reduce this even more, until the target of 100 per cent post‐consumer recycled content is reached,” he says.

While energy consumption in the operational phase of buildings has been significantly reduced in the last 30 years, by combining low-demand, efficient installations, off-grid or on-grid renewable energy and the proper management, similar reductions in energy consumption have not been made in the materials production phase, Kameshki points out.

Furthermore, with efficient buildings now using larger volumes of material, the energy content is a decisive factor. Hydro Circal 75R, with its low built-in energy level, is a major step towards reducing the impact of materials on the life cycle of a building.

“Technal windows have contributed greatly to the improvement of insulation and energy efficiency and Hydro Circal 75R represents a much-awaited solution among environmental consultants, architectural professionals and, consequently, end users,” he claims.

The introduction of the post-consumer certified recycled aluminium window comprising Hydro Circal 75R is a decisive step for the Technal brand in line with its efforts towards a certified circular economy, while following the course set by the European Union.

In September 2020, the European Union President Ursula von der Leyen expressed the desire to create a new Bauhaus (German for construction house) Green, within the framework of the Green Deal, where new methodologies, tools, databases, demonstration cases and industrial transformations are developed that promote a change in the model – from extract‐manufacture‐use‐discard to recycle‐manufacture‐use-recycle. This new environmental and economic project aims to tackle, among other factors, carbon emissions and reduce the impact of production activity. Technal is fully prepared for this target, having already been working over several years to improve its industrial processes, he states.

In line with its goals towards a certified circular economy, Technal says it extrudes its profiles using low CO2-footprint aluminium, using renewable energy and recycling post-consumer aluminium.

A Hydro plant in Dormagen, Germany, has developed a technology to effectively separate aluminium from other metals and to use each for correct recycling. This system allows only the recycled aluminium with the right alloy to be used to produce windows that are sent to Hydro’s smelting plants.

“Remelting aluminium for new uses require only five per cent of the energy needed to produce the primary aluminium. Through the use of renewable power and modern technology, Hydro is able to produce cleaner aluminium than ever before. The production process is independently certified according to ISO 14064 and completely traceable, and the product is certified by Det Norske Veritas (DNV), an independent certification company with headquarters in Oslo, Norway. The Hydro group was the first company to achieve recognition from the Aluminium Stewardship Initiative (ASI), the internationally recognised standard for assessing sustainability throughout the life cycle of aluminium, from its extraction and production to the use and recycling thereof,” he says.

Technal classifies its range under the criteria of the Cradle to Cradle seal, an independent institute that certifies products and processes from a circular economy perspective. While offering products with a reduced impact on the environment, Technal can provide all the certifications that help in achieving the different green standards that are currently on the market such as LEED, BREEAM, DGNB, WELL, VERDE, LEVEL(s).

“These certifications include Environmental Product Declarations (EPD) for construction from the Institut Bauen und Umwelt eV, ISO certifications for quality systems and environmental management, official test certificates, Cradle to Cradle certifications and others. Its systems carry the sustainability product pass of the ift Rosenheim.

“Technal’s innovative system solutions assure developers, architects and investors that their projects meet the requirements of sustainable certification and their designs will already be meeting tomorrow’s standards.” Kameshki concludes.

- First certified recycled aluminium window

- Circal effective in reducing CO2 emissions

- Geberit records major drop in eco impact

- Armstrong offers free trial of its Pump Manager

- Demag cranes deployed for power plant work

- Questers join Gulf Ready Mix fleet

- Demand-controlled ventilation marvel