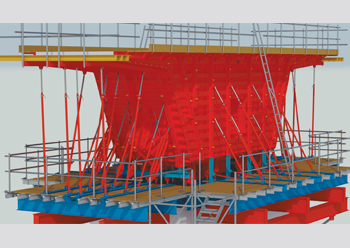

RMDK used 3D visualisation to ensure the final formwork solution would meet all requirements of the MTHL project.

Covid-19 and the rise of digital engineering

WASSIM DAHER, Chief Engineer Middle East and India at RMD Kwikform, highlights how, in the wake of the Covid-19 pandemic, digital engineering capabilities are set to become a key differentiator for contractors and engineers in the region seeking efficiency gains, whilst helping the industry navigate disruptions and mitigate risks.

01 September 2021

Over the past year, businesses in every industry have faced the challenges of a global pandemic. While some industries have thrived, others have suffered trade restrictions, drastic drops in demand, and reduced availability of materials and workers. The construction industry is one sector that has been hit particularly hard by Covid-19.

As countries within the Middle East began experiencing outbreaks, governments took action to protect their people, with varying degrees of impact upon construction works. The pandemic resulted in the introduction of additional health and safety measures, restricted movement of labour, supply chain difficulties, challenges across the region, and the widespread delay and suspension of projects.

Nevertheless, although the past year has been challenging, it has presented opportunities for the construction industry to not only survive the struggles it faces now and long into the future but to overcome its historic barriers to change. The nature of the external pressures exerted by the global pandemic has meant the industry has been forced to adapt and work differently.

Time to innovate

For many in the industry, the pandemic has accelerated innovation. Long before Covid-19, many processes, operations and procedures used by construction businesses were considered outdated, with recent events further bringing this to light. A recent McKinsey report1 has predicted big changes across the construction industry over the next decade, adding that the bulk of short- and long-term pandemic-driven issues will be solved with technology. It reports that the mandate for technological adoption in construction has never been stronger, with the pandemic ‘only serving to provide additional urgency to the pre-existing productivity and data-visibility issues facing construction companies’.

Seizing digital opportunities

A key benefit of digital engineering tools is how seamlessly they can help stakeholders view and interrogate a project. The latest digital engineering tools also offer high-quality 3D visualisations of temporary works on a build, helping to break down communication barriers and ensure transparency across the supply chain for any specified systems. This results in reduced risks, as any potential issues can be quickly raised and remedied prior to construction of a temporary works solution taking place. Digital solutions also streamline work processes, as the systems and product details can be viewed in an accessible format.

Digital technology can also play a crucial role in helping contractors win tenders for projects. By using digital engineering technology, recommendations on project structures and construction phases, not to mention the ability to identify any potential challenges, can be ascertained. In addition, digital tools can help illustrate to users how to best assemble, move and dismantle equipment ahead of delivery, ensuring site operatives stay in line with social distancing measures, or even map out areas of work so that touchpoints can be better controlled.

Digitally driven

In response to evolving working practices in the industry, which have been further accelerated by the outbreak of Covid-19, leading international manufacturer and supplier of formwork, falsework, groundwork and safety systems, RMD Kwikform (RMDK), has created LocusHUB, a one-stop hub for all its digital innovations and resources. Available at locushub.rmdkwikform.com, it brings together all RMDK’s digital assets including apps, product videos, CAD resources and technical data.

Now is the time for the construction industry to fully embrace new ways of working to help drive substantial operational improvements and maximise potential in the ‘new normal’. Those businesses willing to use technology well and transform how they work by fast-tracking digital transformation and optimising digital skills will stay ahead of the competition.

3D vision for the Mumbai Trans Harbour Link

RMDK secured the contract to supply a temporary support solution for Phase Two construction of the Mumbai Trans Harbour Link (MTHL), a 22-km-long, six-lane sea bridge in development over the Mumbai Harbour in Maharashtra, India. When completed, the MTHL will be the longest sea link in India with approximately 17 km stretching over the sea and 5 km covering viaducts on land. The Mumbai Metropolitan Region Development Authority (MMRDA) has undertaken the implementation of the expressway, connecting Sewri on Mumbai side to Chirle on Navi Mumbai side, to ease traffic congestion.

RMDK used digital tools to design and supply bespoke special formwork solutions, which included solid and hollow piers, portal beams and large in-situ pier heads. One key challenge to overcome included bridge segment formwork that was required to be self-supporting without having to utilise ground bearing shoring systems. The segment also needed to be lowered after casting onto the permanent bearings; therefore, hydraulic jacks were incorporated into the formwork design.

This multi-layered solution was modelled in 3D using AutoCAD and MasterSeries to better assess its practicality in relation to clash detection and in structural modelling of the pre-and-post-pouring sequences, as well as the assessment of the jacking requirements. Measurable benefits of using these digital tools included better design visualisation, for both client and engineers, improved construction sequence planning, value engineering and design integration.

RMDK used 3D visualisation, working closely with main contractor, Daewoo- Tata Projects Limited JV, to ensure the final formwork solution met all requirements and achieved the highest standards of safety, quality and efficiency. Work on the MTHL is expected to be completed by September 2023.

1. McKinsey & Company, ‘Rise of the platform era: The next chapter in construction technology’, https://www.mckinsey.com/industries/private-equity-and-principal-investors/our-insights/rise-of-the-platform-era-the-next-chapter-in-construction-technology.

- 3D printing set to transform sites

- Dar Al Arkan launches 3DCP in kingdom

- UHPC demonstrates exciting prospects

- Covid-19 and the rise of digital engineering

- Cifa unveils ‘five-arm’ pump

- Paschal shows forte on Dubai Hills villas