Fire-retardant ACPs set for global arena

Alubond’s latest A1 panels have been making a mark internationally because of their properties, with their latest successes having included five mega projects in the US.

01 October 2021

Mulk Holdings’ Alubond brand has embarked on an aggressive global expansion plan which will see it establish a direct presence in multiple major markets, according to the chairman of the UAE-based diversified multinational business conglomerate.

“We are setting up offices and showrooms in the US, Canada, Egypt, Saudi Arabia and other regions,” Shaji Ul Mulk, Chairman of Mulk Holdings International, tells Gulf Construction. “Currently, we have factories in the UAE, Oman, Serbia and India, making us the largest aluminium composite panels (ACP) manufacturer in the world, with production capacities in excess of 25 million sq m per year.”

The company in August announced a partnership with Park International Investments and Silver Heights Real Estate to set up Alubond USA, after securing exterior façade contracts for five mega projects including Wyndham Hotel, marking its entry into the US.

|

|

Kingston tower ... a key project in Ajman. |

This is thanks to the excellent properties of the ACP which afford exceptional fire resistance, according to Ul Mulk.

Alubond’s ACP is a 4-mm composite panel comprising two layers of aluminium skin bonded to an inner core of minerals in a continuous co-extrusion process. The Fire-Retardant A1 ACP (FR-A1) has more than 97 per cent mineral core, making it highly fire-resistant and fire-retardant.

Alubond also offers the FR-A2 grade ACP, which has more than 92 per cent mineral core.

“Alubond is a world-class brand that offers the highest fire-resistant ACPs and cladding systems. The product specifications meet the stringent Civil Defence Code criteria for high-rise construction. It is the only brand in the Middle East offering the A1 range of fire-resistant ACPs,” Ul Mulk remarks.

The A1 grade fire-rated core and a proprietary bonding system for ACPs was developed exclusively for Alubond at the end of late last year by Metal Plast Industries, a fully-owned subsidiary of Mulk Holdings International.

A technology breakthrough, the development of the core is considered a game-changer in the fire rating standards of exterior facades. Alubond A1 has the lowest heat release over high lamination, such as heat value less than 1.0 MJ/kg and peel strength above 7.0 Newton per sq m.

|

|

FR-A2 grade ACPs have been supplied for the Vida Dubai Mall. |

In terms of aesthetics, Alubond offers a vast range of colours and finishes in solid, metallic, wood, stone, prismatic, sparkling and mirror finishes. Mulk Holdings also produces custom colours as per clients’ requirements.

“Aluminium composite panels are the favoured material for external facades by architects, as they provide the flexibility to bring amazing designs to life. They are highly durable with long warranties and offer ease of fabrication and installation,” he says.

Turning to sustainability, he says: “We strive to ensure minimum production wastage and recycle ACP core internally and aluminium skins as well. Our group company Metalplast is responsible for this and contributes majorly to our recycling efforts. Our production processes are efficiently designed to avoid energy wastage.”

Alubond products have been installed on prestigious projects in the region including the Address Hotel in Downtown Dubai and various airports.

As one of the approved global suppliers for Jaguar Land Rover showrooms, Mulk Holdings has recently supplied to the luxury vehicles company’s showroom projects in Saudi Arabia. The fire-resistant panels supplied are finished as per the luxury vehicles brand’s specified custom colours.

The company has also recently supplied FR-A2 grade ACP for the World Trade Centre 2, Vida Dubai Mall in Dubai Marina and Kingston tower in Ajman.

|

|

A cross-section of an Alubond ACP. |

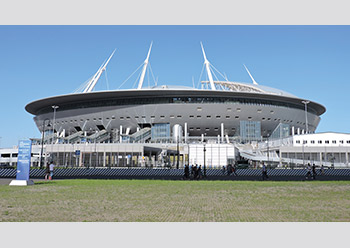

Among prestigious projects in the international market, Alubond products have been installed at the Zenit Arena also known as St Petersburg Stadium in Russia, which hosted Fifa World Cup 2018.

Mulk Holdings has used its business acumen as well as ensured that it has the required product certifications to enable it to penetrate these markets.

Ul Mulk explains: “We were able to establish a factory in Europe and secure our position by strategically locating it in Serbia that offers various advantages, and geographically the location enables us to serve the UK, Europe and Russia. We have all the necessary regional certifications.”

Mulk Holdings also manufactures aluminium doors, windows, balustrades and cladding systems along with complete fabrication for external facades. We also offer curtain-wall systems that have been supplied to various commercial, residential and recreational projects.

“We have also integrated forward and backward production facilities, wherein we manufacture the core, bonding adhesives, protective films used in ACP production. We also have paint production facility along with coil coating lines,” he says.

- Fire-retardant ACPs set for global arena

- Bauporte sees demand for threat-resistant doors

- Reynaers adds Al Khobar landmark to portfolio