Faro allows to compare scans over time to capture structural changes such as shift or drift with 4D monitoring.

Digital route to verification

Digitalisation is bringing a major shift in the construction industry, says VITO MARONE of Faro* as he elaborates on state-of-the-art techniques for construction verification.

01 May 2018

Digital is big everywhere; it’s big in our social activities, big in our homes and now - albeit almost the last to catch on – it’s big in the architecture, engineering, construction and operation (AECO) industry.

More often now, we see virtual 3D models enriched with data sources being developed through the design process in every sector of the built environment. These ‘digital twins’ are in their infancy at the design stage and are expected to mature through the construction process and into the operational life of the ‘asset’ to test and analyse its use and performance.

The ultimate aim is that a digital twin continuously learns and updates itself from multiple sources to represent its near real-time status, working condition or position. So how do we check if the physically constructed reflects the ‘as designed’ digital twin?

To understand that, let’s consider the traditional way of checking (verifying) what is actually constructed versus what has been designed.

In most cases today – even with an up-to-date building information modelling (BIM)-authored model – the checking of physical construction against a virtual model is rarely as thorough as it should be. Often an approach along the lines of ‘this is the way we used to do it’ is carried over to checking against 2D drawings extracted from a model.

Hence, we have a range of solutions from ‘surveyors on site taking key measurements upon completion and marking up drawings’ through to ‘surveyors on site measuring at key stages of construction and producing/updating digital drawings for comparison’.

|

|

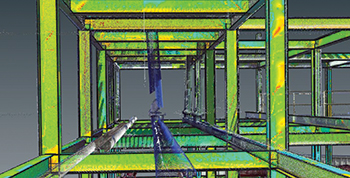

Users can validate their 3D scan to their digital design files with a 3D analysis |

It’s fair to say that although methods such as these have seen buildings completed and functioning today through 2D documentation techniques, it’s not necessarily going to take us confidently into the new digital age.

The advent of BIM processes creating data-rich virtual models of buildings, roads, rail lines and waterways with links to specification, cost and time data sources is enabling a construction business environment much more akin to that of the automotive or product manufacture businesses.

Therefore, clients are beginning to use the valuable data for ongoing business operations rather than simply procuring a ‘building that their business takes place in’. In fact, it’s sometimes now a requirement for construction teams to demonstrate that what has been built in the real world performs the way it was designed and signed-off.

Just as vehicle or electronics buyers won’t accept for products that don’t match the stated performance, building owners shouldn’t stand for delivered projects that don’t match the stated or designed performance.

It’s this very fact, alongside often quoted figures of a 30 to 40 per cent energy performance gap between ‘as designed’ and ‘as constructed buildings’, that has led the UK government to include the need for construction verification via point cloud or LiDAR techniques in their BIM process known as BIM Level 2 (PAS1192-2:2013 Section 10.2).

So how does the modern construction company deal with these digital requests for verification? Whilst this is a state-of-the-art process and a big shift in the construction industry, what Faro is doing here is bringing 20 to 30 years of experience from the manufacturing industry to construction.

Assuming readers are comfortable with the process of ‘laser scanning’, Faro’s BuildIT software provides the ability to compare that measured survey with a 3D model or indeed another scan or analyse the scan itself. The software uses a very intuitive and simple process.

Once the software is pointed to the design model and the measured survey and/or input device, the results are quickly displayed in the most appropriate way you choose.

|

|

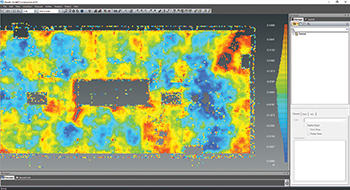

BuildIT performs a full digital tolerance evaluation of any project feature, such as floor flatness |

Currently, the software has several features that it does very well, but there’s more to come in planned future versions. But even with the standard features of Version One, the return on investment (ROI) is through the roof.

In a nutshell, technological advances now allow construction companies to verify much more precisely and quickly using easily captured digital representations of the real world against designed and modelled building works.

It’s not a static process either; the (BuildIT) software can be used in real time, feeding in measured data, analysing it and then, using a tracer, project a pattern on the surface where areas are out of tolerance.

Beyond this, in marrying the software and hardware together (including non-Faro hardware) contractors can continuously record what has been built for various purposes. It’s useful for delving into the past too; the software maintains a record of the measured surveys and can allow users to see what was built and when, then how it was covered up during the construction stages.

The output from the BuildIT software (in various forms, from traditional printed reports to real-time projection onto site elements) can be used by various parties for tasks such as incremental sign-off of construction work, conformity to building standards and generally to determine the correct location of larger items such as walls, ducts, doors, etc.

With a multitude of uses in applying this manufacturing industry approach to the many facets of the construction industry already in mind, it’s exciting to begin to think about just how many people will be helped, how many days or weeks will be saved in construction programmes, how much less material will be wasted and how much better our industry will be.

In conclusion, construction verification is a fundamentally important part of the new era of the digitally-enabled environment. It’s the process of developing and updating the digital twin that is helping to drive out huge inefficiencies of the construction industry and enabling the creation more technically complex solutions for our modern world.

What Faro has released is a very complete first version of its software for the construction industry. It’s also a toolkit and the company is very excited to see what the industry will do with it.

*Faro of the US is a trusted source for 3D measurement, imaging and realisation technology. Headquartered in Florida, it has a technology centre and manufacturing facility covering 8,400 sq m in Exton, Pennsylvania. Its regional global headquarters are located in Stuttgart, Germany, for Europe; and Singapore for the Asia-Pacific region.

- Digital route to verification

- Al Shirawi to boost efficiency with Aconex

- LocusEye renders highly realistic 3D models