Perkins’ solutions extend engine life

01 October 2019

Electric power customers in the Arabian Gulf region are increasingly turning to Perkins’ comprehensive range of overhaul products to affordably extend the life of their engines and avoid disruptive downtime, according to Ian Bradford, aftermarket product manager at Perkins, a leading provider of diesel and gas engines.

Reliability and longevity are hallmarks of Perkins products. However, at some stage of their life, certain components may need to be overhauled.

Overhauling an engine is the process of replacing key components, but retaining its core elements, such as the main engine block, said Bradford, adding that the advantage of doing this is performance of the engine is greatly improved performance at a considerably lower cost than replacing it with a new one.

For customers in the electric power sector, overhaul products are becoming increasingly popular. By carrying out preventative maintenance, such as an overhaul, customers can ensure they prolong the life of the engine, increase the return on investment and minimise the potential for downtime, he added.

Bradford said people in the Gulf choose Perkins to power their generator sets because of the company’s reputation for reliability and engine durability.

“By utilising Perkins’ overhaul solutions, customers can significantly extend the life of their engines. They continue to get maximum performance, while reducing their operating and owning costs,” he said.

He added many of Perkins’ engines, such as the Perkins 4000 Series, can be installed in hard-to-reach locations. “The physical challenges of replacing engines in these locations are very high, particularly if an engine fails and is not repairable. With Perkins overhaul products, a customer is protecting the engine’s core and their investment,” he said.

Overhauling involves working on the core of the engine and this isn’t a job that is done often. That’s why it’s important to ensure it’s done right – with genuine Perkins parts and Perkins-approved engineers performing regular maintenance to avoid critical failure, Bradford added.

The benefits of using overhaul products, he said, are clear when compared to the costs involved in replacing the complete equipment set-up.

Perkins offers a complete range of overhaul options, from the Perkins 400 Series all the way through to the Perkins 4000 Series – of which there are many installed in the Gulf region.

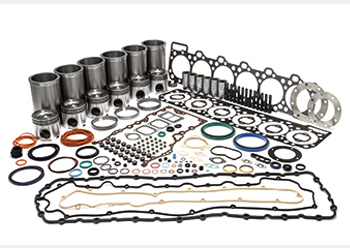

The overhaul product range is made up of a number of different parts groups including major components, cylinder components, rotating components, valvetrain, gaskets and seals, and is further complemented with an array of overhaul kits.

“Our overhaul kits help customers address some of the most common overhaul requirements,” Bradford said. “They add convenience when ordering by providing a large number of components under a single parts number, provide a cost saving compared with purchasing individual parts, and ensure customers have all the right products at the right time.”

Perkins’ overhaul parts all meet the latest specifications. So where improvements have been made to components, customers see those benefits in the form of improved performance and running costs.

Customers also have the option to buy under- and oversized parts, if required, that enable them to regrind/rebore crankshafts and cylinder blocks, to help them get more life from their engines.

“Our products are designed with customers in mind and we constantly gather feedback. As a result, we have a new range of single cylinder kits for our 4000 Series engines, as well as kits for other engines including the 400 and 1100 Series. New assembly kits are also available, which provide fully assembled larger components that can easily be dropped in,” Bradford said.

Perkins distributors have also experienced the growing value of overhaul products to their electric power customers.

The highly-trained Perkins distribution network has the knowledge, experience and tools to ensure overhaul work happens in a timely way, without problems.

Whichever overhaul option customers choose, it’s vital that they purchase and install genuine Perkins parts, Bradford emphasised. “Non-genuine parts will not be manufactured to meet the specific needs of the engine. Any mismatch, or fitting of the wrong part, can cause serious engine damage.

“Using genuine parts ensures the engine is returned to its original performance – or better – after an overhaul. Customers will maintain confidence in the engine and generator, maximise its life, and continue to reduce their running costs long into the future,” he concluded.

- Bahrain, UAE projects win Aga Khan award

- Diyar Al Muharraq set for giant park opening

- Kuwait flags off $358m city development deals

- QP issues EPC tender for North Field facilities

- Perkins’ solutions extend engine life

- Case showcases prowess of India plant

- GCC steel firms ‘must shift focus to manufacturing’

- 190 Otis lifts for Kuwait Airport Terminal 2

- Raysut Cement embarks on expansion plans

- National Steel to build mega complex in Salalah

- In brief